[ad_1]

US aerospace and protection contractor L3Harris is leveraging the Worldwide House Station (ISS) Nationwide Laboratory to check sturdy supplies essential for satellite tv for pc element manufacturing utilizing 3D printing.

Earlier than 3D printed supplies may be trusted for spacecraft elements, thorough testing is critical to make sure their resilience within the harsh atmosphere of low Earth orbit (LEO), in response to the corporate. L3Harris has launched a challenge to check a 3D printed radio frequency (RF) circuit and varied materials samples on SpaceX’s twenty seventh Industrial Resupply Companies (CRS) mission. This initiative follows a 2021 experiment on the ISS, which offered invaluable information over two months. On this iteration, L3Harris is extending its testing to incorporate photonic materials for photonic built-in circuits, a expertise much like pc chips however utilizing gentle as an alternative of electrons.

“We’re excited to check the 3D printed supplies for six months and examine the brand new outcomes with earlier ISS experiments and floor exams,” mentioned Arthur C. Paolella, senior scientist and technical fellow with L3Harris, an aerospace and protection trade chief. “The power to 3D print supplies to be used in area opens up new potentialities for satellite tv for pc design and building whereas making spacecraft manufacturing cheaper and environment friendly.”

Optimizing supplies by way of in-space efficiency testing

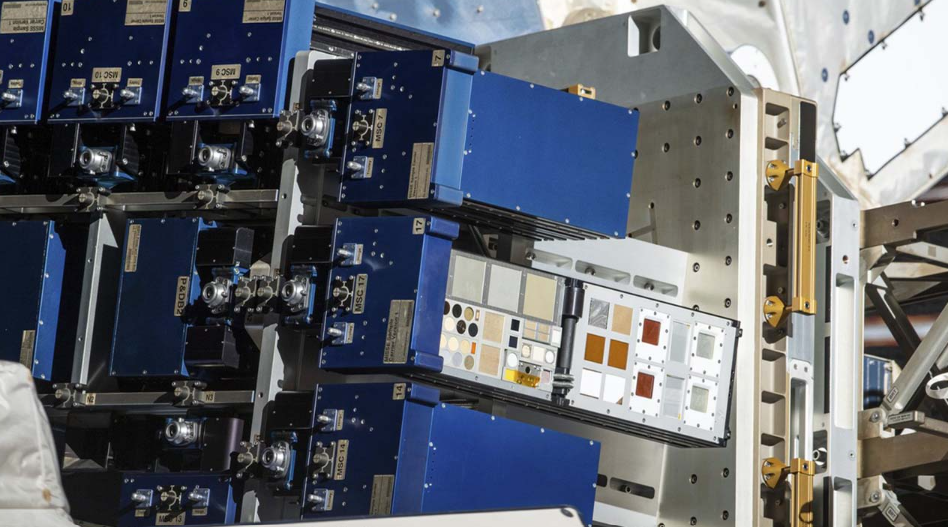

Eduardo Rojas, director of the Wi-fi Units and Electromagnetics Laboratory at Embry Riddle Aeronautical College, alongside along with his college students, is helping with this enterprise. Managed by ISS Nationwide Lab Industrial Service Supplier Aegis Aerospace and affixed to the ISS exterior, the experiment will make the most of the MISSE Flight Facility. Uncovered to the trials of area, the fabric samples will bear varied stressors, together with excessive temperatures and radiation, to guage their efficiency underneath circumstances much like these skilled by satellites.

Paolella acknowledged that the outcomes obtained from these exams will information the refinement and growth of supplies for integration into satellite tv for pc manufacturing processes. Furthermore, utilizing photonic built-in circuits holds promise for enhancing satellite tv for pc communications by probably decreasing measurement, weight, and energy necessities whereas rising information transmission capabilities. L3Harris is exploring extra purposes for 3D printed supplies in area, akin to in-orbit manufacturing and restore, past satellite tv for pc elements. These efforts spotlight a concerted effort to leverage superior applied sciences to enhance area exploration and satellite tv for pc expertise.

“Whereas we will check the sturdiness of those supplies on Earth towards one or two of those elements at a time, on the ISS, we will check each potential hazard—and suddenly,” Paolella mentioned.

Novel developments in area manufacturing

Using 3D printing for area manufacturing has picked up a big tempo up to now few months. One of many latest examples contains the Metal3D challenge, developed by AddUp in alliance with Airbus Defence & House underneath a European House Company (ESA) contract, which launched a metallic 3D printer for area purposes. Co-funded by Airbus, this printer goals to guage additive manufacturing in sustained microgravity.

Launched to the ISS by NASA Mission NG-20, it should bear testing within the Columbus module. In line with Airbus, the operational printing was anticipated in late February or early March. Airbus highlights the potential of in-space manufacturing to cut back reliance on Earth-based provide chains. The experiment goals to evaluate the standard of metallic printing in area and inform future extraterrestrial missions.

Final yr, Orbital Composites secured a $1.7 million U.S. House Drive contract to advance In-space Servicing, Meeting, and Manufacturing (ISAM) antennas. Collaborating with trade giants like Axiom House and Northrop Grumman, the staff aimed to rework Satellite tv for pc-Based mostly Mobile Broadband and House-Based mostly Photo voltaic Energy. The corporate deliberate to launch its first House Manufacturing facility module and set up an ISAM “laboratory” on Axiom Station. With plans for growth into Geostationary Orbit, Orbital additionally partnered with House Logistics to refine ISAM capabilities for GEO purposes.

What 3D printing developments do the trade leaders anticipate this yr?

What does the Way forward for 3D printing maintain for the subsequent 10 years?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Business publication or comply with us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you on the lookout for a job within the additive manufacturing trade? Go to 3D Printing Jobs for a number of roles within the trade.

Featured picture exhibits the Supplies Worldwide House Station Experiment (MISSE) Flight Facility on the outside of the area station exposes supplies to the cruel atmosphere of area. Picture through NASA.

[ad_2]

Supply hyperlink