[ad_1]

Mar 15, 2024

(Nanowerk Information) 3D-printed microscopic particles, so small that to the bare eye they appear like mud, have purposes in drug and vaccine supply, microelectronics, microfluidics, and abrasives for intricate manufacturing. Nevertheless, the necessity for exact coordination between gentle supply, stage motion, and resin properties makes scalable fabrication of such customized microscale particles difficult. Now, researchers at Stanford College have launched a extra environment friendly processing approach that may print as much as 1 million extremely detailed and customizable microscale particles a day.

“We are able to now create rather more advanced shapes right down to the microscopic scale, at speeds that haven’t been proven for particle fabrication beforehand, and out of a variety of supplies,” stated Jason Kronenfeld, PhD candidate within the DeSimone lab at Stanford and lead writer of the paper that particulars this course of, printed in Nature (“Roll-to-roll, high-resolution 3D printing of shape-specific particles”).

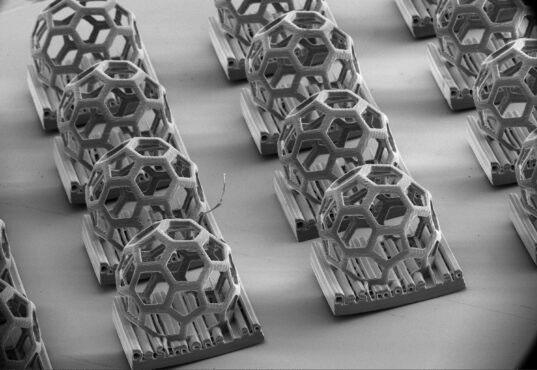

The 3D-printed DeSimone lab brand, that includes a buckyball geometry, demonstrates the r2rCLIP system’s capacity to provide advanced, non-moldable shapes with micron-scale options. (Picture: DeSimone Analysis Group, SEM courtesy of Stanford Nano Shared Services)

This work builds on a printing approach referred to as steady liquid interface manufacturing, or CLIP, launched in 2015 by DeSimone and coworkers (Science, “Steady liquid interface manufacturing of 3D objects”). CLIP makes use of UV gentle, projected in slices, to remedy resin quickly into the specified form. The approach depends on an oxygen-permeable window above the UV gentle projector. This creates a “lifeless zone” that forestalls liquid resin from curing and sticking to the window. In consequence, delicate options might be cured with out ripping every layer from a window, resulting in quicker particle printing.

“Utilizing gentle to manufacture objects with out molds opens up an entire new horizon within the particle world,” stated Joseph DeSimone, the Sanjiv Sam Gambhir Professor in Translational Drugs at Stanford Drugs and corresponding writer of the paper. “And we expect doing it in a scalable method results in alternatives for utilizing these particles to drive the industries of the longer term. We’re enthusiastic about the place this may lead and the place others can use these concepts to advance their very own aspirations.”

Roll to roll

The method that these researchers invented for mass producing uniquely formed particles which might be smaller than the width of a human hair is paying homage to an meeting line. It begins with a movie that’s rigorously tensioned after which despatched to the CLIP printer. On the printer, lots of of shapes are printed without delay onto the movie after which the meeting line strikes alongside to clean, remedy, and take away the shapes – steps that may all be custom-made primarily based on the form and materials concerned. On the finish, the empty movie is rolled again up, giving the entire course of the identify roll-to-roll CLIP, or r2rCLIP. Previous to r2rCLIP, a batch of printed particles would have to be manually processed, a sluggish and labor-intensive course of. The automation of r2rCLIP now allows unprecedented fabrication charges of as much as 1 million particles per day.

If this feels like a well-known type for manufacturing, that’s intentional.

“You don’t purchase stuff you possibly can’t make,” stated DeSimone, who can also be professor of chemical engineering within the Faculty of Engineering. “The instruments that almost all researchers use are instruments for making prototypes and check beds, and to show vital factors. My lab does translational manufacturing science – we develop instruments that allow scale. This is among the nice examples of what that focus has meant for us.”

There are tradeoffs in 3D printing of decision versus pace (Science, “Single-digit-micrometer-resolution steady liquid interface manufacturing”). For example, different 3D printing processes can print a lot smaller – on the nanometer scale – however are slower. And, after all, macroscopic 3D printing has already gained a foothold (actually) in mass manufacturing, within the type of sneakers, family items, machine elements, soccer helmets, dentures, listening to aids, and extra. This work addresses alternatives in between these worlds.

“We’re navigating a exact steadiness between pace and backbone,” stated Kronenfeld. “Our strategy is distinctively able to producing high-resolution outputs whereas preserving the fabrication tempo required to fulfill the particle manufacturing volumes that consultants contemplate important for numerous purposes. Strategies with potential for translational influence should be feasibly adaptable from the analysis lab scale to that of business manufacturing.”

Exhausting and comfortable

The researchers hope that the r2rCLIP course of sees large adoption by different researchers and trade. Past that, DeSimone believes that 3D printing as a subject is rapidly evolving previous questions concerning the course of and towards ambitions concerning the prospects.

“r2rCLIP is a foundational know-how,” stated DeSimone. “However I do imagine that we’re now coming into a world targeted on 3D merchandise themselves extra so than the method. These processes have gotten clearly invaluable and helpful. And now the query is: What are the high-value purposes?”

For his or her half, the researchers have already experimented with producing each arduous and comfortable particles, made from ceramics and of hydrogels. The primary may see purposes in microelectronics manufacturing and the latter in drug supply within the physique.

“There’s a wide selection of purposes, and we’re simply starting to discover them,” stated Maria Dulay, senior analysis scientist within the DeSimone lab and co-author of the paper. “It’s fairly extraordinary, the place we’re at with this system.”

[ad_2]

Supply hyperlink