[ad_1]

Mar 20, 2024

(Nanowerk Highlight) Wooden is without doubt one of the oldest and most ubiquitous supplies utilized by people, with functions spanning building, furnishings, flooring, and past. For hundreds of years, wooden has served because the interface via which we work together with our constructed setting. Nevertheless, whereas wooden excels in its mechanical and aesthetic properties, it has traditionally lacked the power to intelligently sense and reply to the human contact.

Scientists and engineers have been looking for to imbue wooden and wood-derived supplies with tactile sensing capabilities to seize the dear data generated when people bodily work together with picket objects and surfaces. Earlier analysis efforts have demonstrated approaches akin to carbonizing wooden into porous, conductive sponges, coating wooden with graphene, or infiltrating wooden with conductive gel composites. Whereas showcasing attention-grabbing proofs-of-concept, these prior applied sciences confronted limitations of their capacity to be seamlessly built-in into picket objects at scale with out compromising the innate look, really feel and efficiency of the wooden itself.

Nevertheless, latest developments within the rising area of iontronic sensing have opened up new potentialities for realizing clever wooden that maintains its unique properties. Iontronic sensors leverage the distinctive electrical properties of ionic-electronic interfaces to attain terribly high-pressure sensitivity.

Crucially, since ionic conductors and electrolytes are ubiquitous in nature, iontronic sensing can in precept be carried out in nearly any materials—together with wooden – just by introducing a conductive medium. This expertise subsequently gives a promising pathway to seamlessly endow wooden with tactile consciousness.

Constructing upon this potential, a crew of researchers in China has now developed an clever iontronic wooden (iWood) system that integrates extremely delicate strain mapping capabilities into pure wooden via a scalable and non-destructive manufacturing course of. As described of their latest paper revealed in Superior Practical Supplies (“iWood: An Clever Iontronic Machine for Human-Wooden Interactions”), the innovation allows picket objects and surfaces to dynamically sense and digitize advanced human contact interactions with none change to the underlying materials.

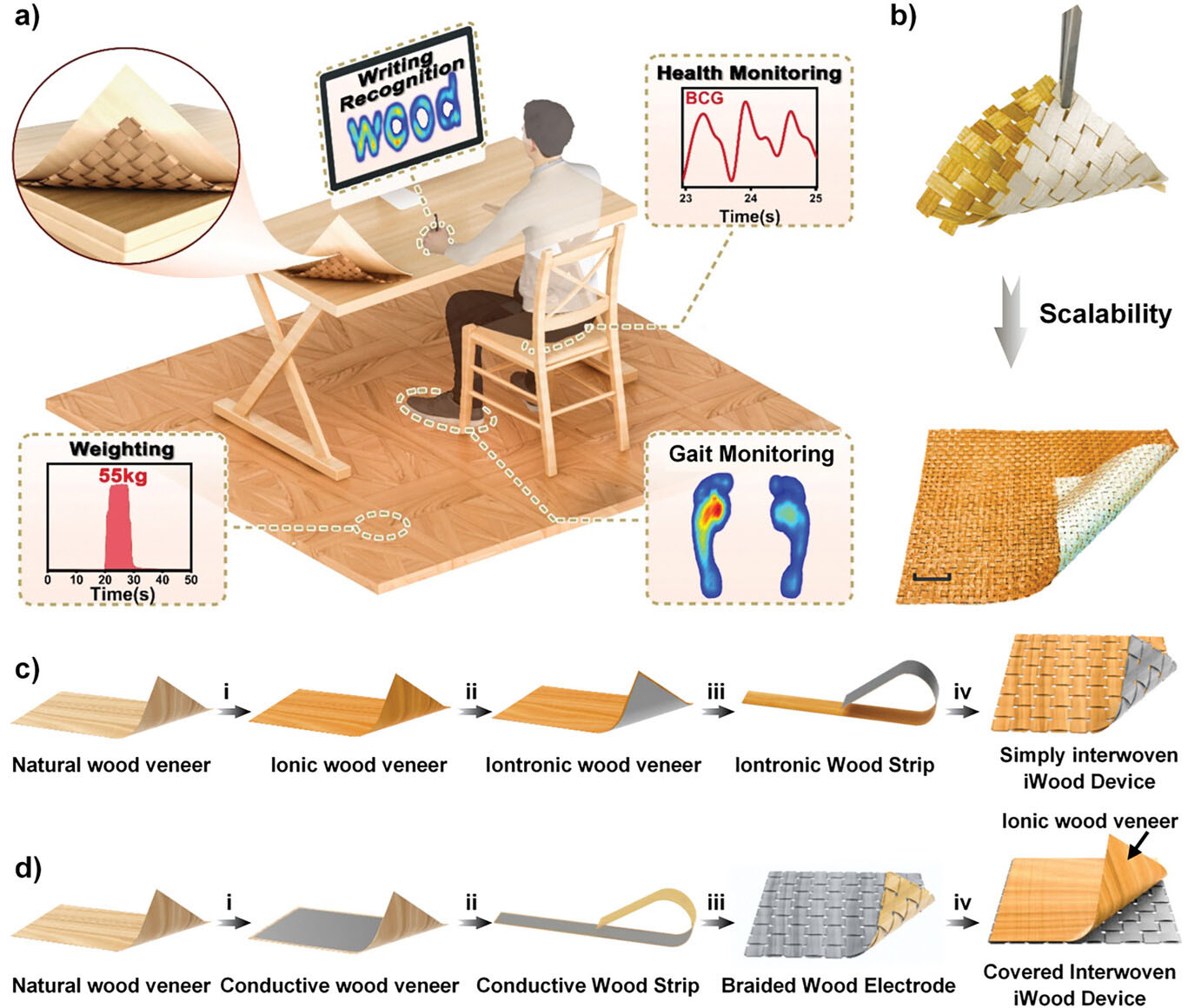

a) Schematic illustration of human-wood interactions utilizing the iWood system. b) The photographs of the scalable iWood system utilizing the braiding course of. c) The preparation of the merely interwoven iWood system. i) Ionizing of pure wooden veneer into ionic wooden veneer, ii) floor metallization of ionic wooden veneer into iontronic wooden veneer, iii) reducing iontronic wooden veneer into strips, iv) braiding iontronic wooden strips into the merely interwoven iWood system. d) The preparation of the lined interwoven iWood system. i) Floor metallization of pure wooden veneer into conductive wooden veneer, ii) reducing conductive wooden veneer into strips, iii) braiding conductive wooden strips into the braided wooden electrode, iv) protecting ionic wooden veneer on the electrode to kind the lined interwoven iWood system. (Reprinted with permission by Wiley-VCH Verlag)

On the core of the iWood system is a specifically developed “ionic wooden” materials, created by infusing pure wooden with an ionic liquid which is then immobilized by way of hydrogen bonding to the cellulose fibers. This course of leverages the pure porosity and structural channels in wooden to attain a fair distribution of ionic species with out disrupting the integrity of the wooden on a macroscopic degree.

Notably, the researchers optimized the ionic wooden to own each excessive ionic conductivity for electrical sensitivity and glorious mechanical stability to stop ionic liquid leakage even underneath giant pressures.

To assemble purposeful iWood units, skinny versatile strips of the ionic wooden are interwoven collectively in a grid-like structure, with a number of the strips selectively coated in steel to function conductive electrodes. Every intersection between an ionic wooden strip and a conductive wooden strip kinds a pixel-like sensing node, wherein the contact strain modulates the capacitance of the ionic-electronic interface. By measuring this capacitance change in every pixel, the iWood system generates a high-resolution strain map.

By means of rigorous mechanical modeling and testing, the researchers systematically optimized the efficiency of the iWood system, assessing key parameters akin to sensitivity, strain vary, response pace, and sturdiness. The outcomes exhibit that the iWood achieves a exceptional sensitivity of over 30 nanoFarads per kilopascal, a speedy response time underneath 5 milliseconds, and constant efficiency over greater than 10,000 loading cycles. Additional customization of the ionic wooden properties, for instance by tuning the porosity via chemical therapy, enabled the sensing vary and sensitivity to be tailor-made for various functions.

To validate the real-world performance of the expertise, the crew fabricated a sequence of proofs-of-concept spanning interactive desktops, health-monitoring chairs, and clever flooring. For example, a 3,600 sq. centimeter iWood desktop demonstrated correct contact monitoring, gesture recognition, and object classification based mostly on the high-resolution strain patterns generated via regular human interplay with the picket floor. Impressively, a machine studying classifier skilled on the iWood contact information achieved over 99% accuracy in figuring out totally different objects positioned on the desk based mostly solely on their strain footprint.

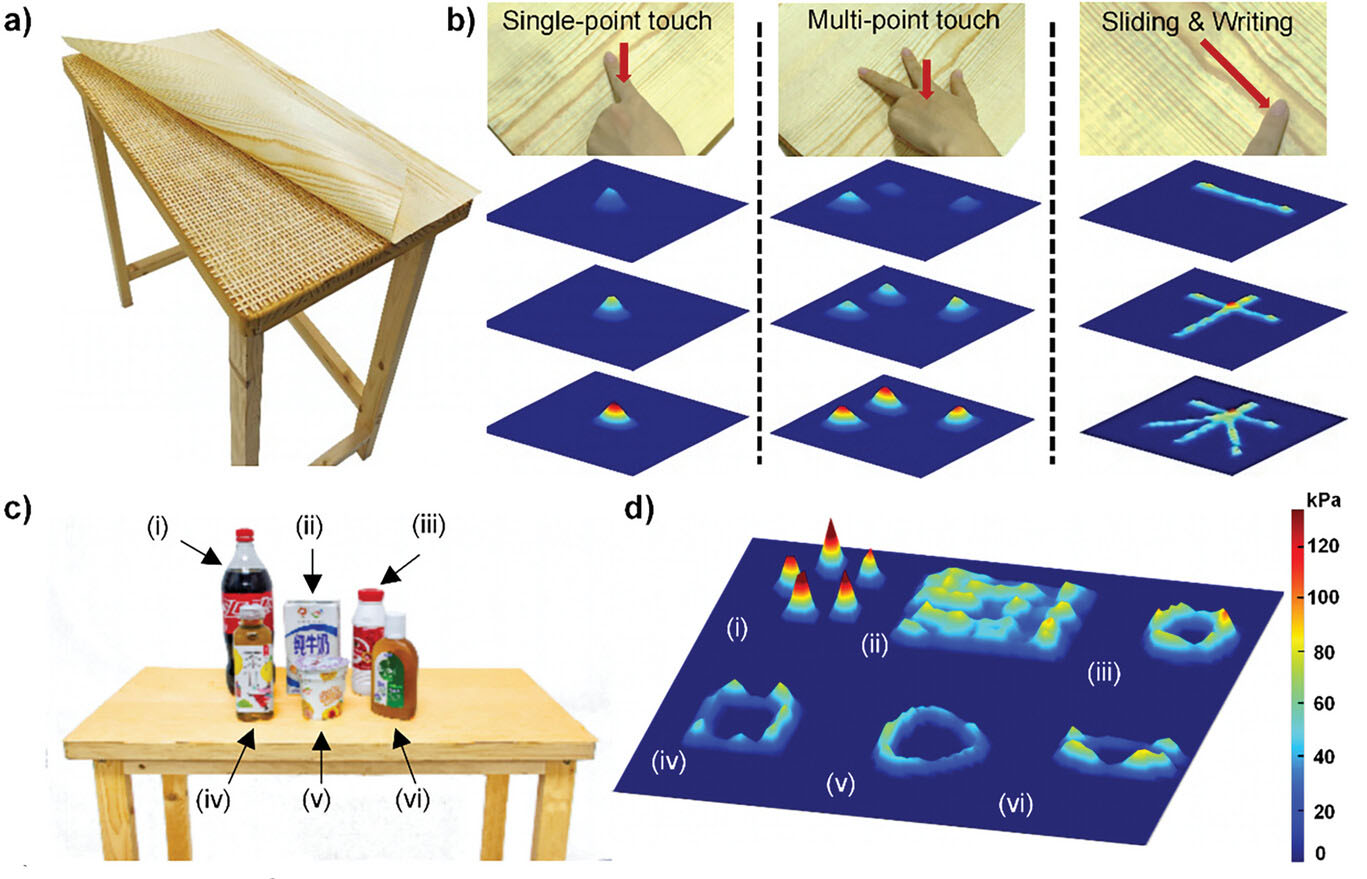

a) {Photograph} of the iWood desk with the lined interwoven system structure revealed, together with b) the picture of the strain mapping outcomes following the single-point contact, multi-point contact, sliding, and writing. c) {Photograph} of various objects positioned on the iWood desk, adopted by d) the corresponding attribute photographs of their contact strain distribution. The numbers in c) and d) symbolize i) Cola drink bottle, ii) Tetra Pak milk, iii) the dairy glass bottle, iv) the tea beverage container, v) the plastic yogurt packaging, and vi) the mouthwash bottle respectively. (Reprinted with permission by Wiley-VCH Verlag)

In one other compelling demonstration, an iWood flooring was in a position to function a complete gait and stability evaluation device by capturing the dynamic strain distribution beneath a person’s toes whereas standing, strolling and leaping. By computing parameters akin to the middle of strain trajectory and floor response drive curve, the clever wooden floor can present clinical-grade insights into an individual’s biomechanics and stability with out the necessity for obtrusive wearable sensors or devoted tools.

Maybe most promisingly, the researchers confirmed that an iWood chair can constantly monitor a person’s coronary heart fee and respiration based mostly on the refined strain variations generated by the physique’s ballistic forces. This use case factors to a future wherein health-critical data might be seamlessly captured via on a regular basis interactions with extraordinary objects and environments.

Trying forward, the improvements launched by the iWood system open up huge potentialities for reimagining how people interact with the picket objects that encompass us daily. By making wooden itself innately clever and responsive, this expertise takes a major step in direction of realizing the complete potential of sensible environments and interactive interfaces. Whereas the iWood continues to be a analysis prototype, one can envision a future the place hyper-aware picket surfaces are ubiquitous in our houses, workplaces, and public areas—silently and unobtrusively monitoring our wellbeing and enhancing our each day lives.

Although challenges stay in scaling up the iWood expertise and validating its long-term reliability, the core ideas and supplies improvements are sound. As such, it probably represents not the conclusion however relatively the start of a brand new paradigm, wherein even probably the most historic and foundational of supplies can develop into imbued with synthetic intelligence. In our more and more sensor-laden and data-driven world, the prospect of sensible wooden could have as soon as appeared like a contradiction in phrases. However with improvements just like the iWood system rising from analysis labs world wide, it won’t be lengthy earlier than the very foundations of our constructed setting can interact with us like by no means earlier than.

By

Michael

Berger

– Michael is writer of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Know-how,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Expertise and Instruments Making Know-how Invisible

Copyright ©

Nanowerk LLC

Nanowerk Publication

Get our Nanotechnology Highlight updates to your inbox!

Thanks!

You could have efficiently joined our subscriber listing.

Grow to be a Highlight visitor writer! Be a part of our giant and rising group of visitor contributors. Have you ever simply revealed a scientific paper or produce other thrilling developments to share with the nanotechnology neighborhood? Right here is publish on nanowerk.com.

[ad_2]

Supply hyperlink