[ad_1]

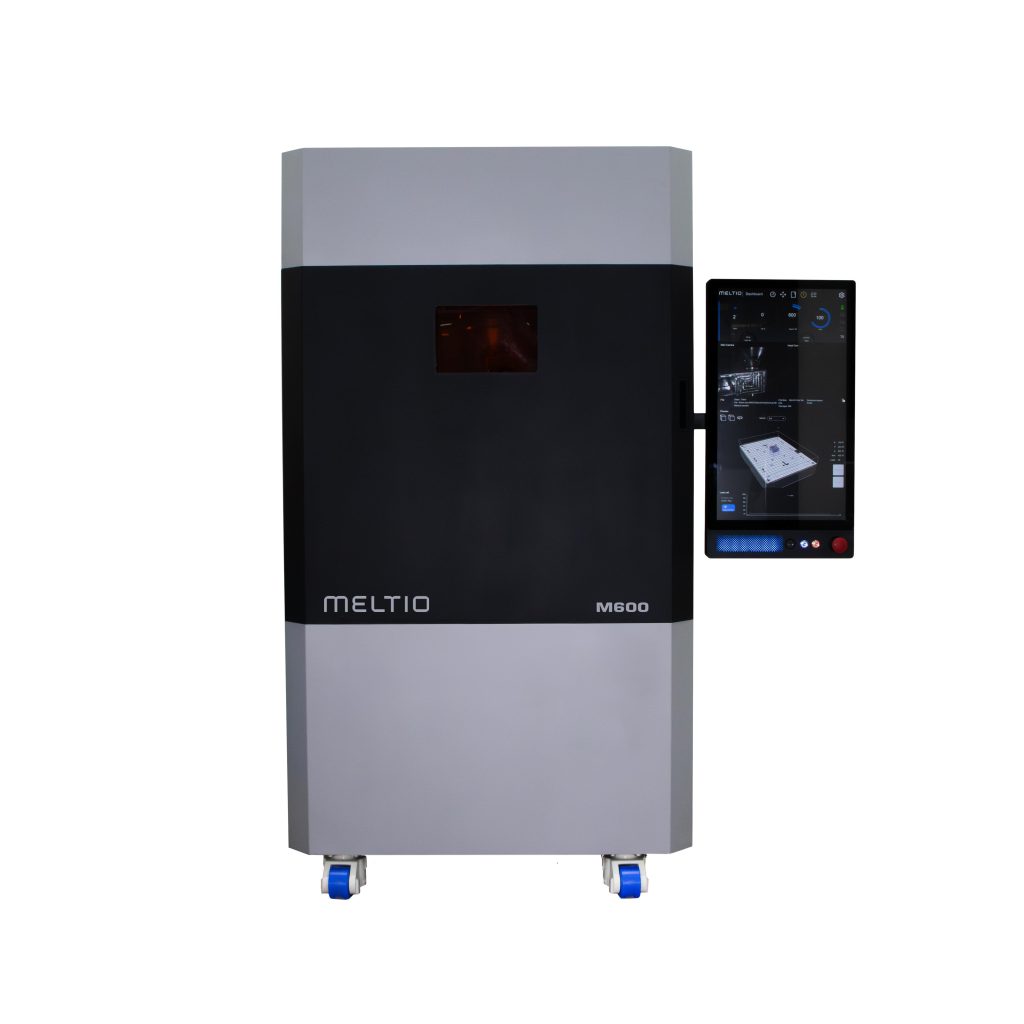

Metallic 3D printer developer Meltio has launched the M600, its latest laser metallic deposition (LMD) 3D printer, on the Additive Manufacturing Customers Group (AMUG) 2024 convention presently being held in Chicago, Illinois.

Incorporating a newly developed Blue Laser deposition head, the 3D printer is designed for industrial-scale manufacturing and is optimized for machine outlets and different 24/7 manufacturing environments.

In keeping with Meltio, the M600 has been developed to beat manufacturing challenges related to lengthy lead occasions, high-cost inventory maintaining, and provide chain insecurities.

“The design temporary for the brand new Meltio M600 was to think about what the proper 3D printer for the machine store would appear to be,” defined Lukas Hoppe, Meltio’s Analysis & Growth Director.

“The overwhelming majority of metallic 3D printed components require post-processing which is carried out within the machine store and, since our ambition is to push the large-scale adoption of metallic additive manufacturing, we’ve a really clear imaginative and prescient that the fashionable machine store is the best level of entry.”

The 3D printer’s autonomous manufacturing capabilities decrease the necessity for handbook person enter. This enables for 24-hour light-out manufacturing operations, growing productiveness and decreasing manufacturing prices. Along with 3D printing metallic components, this new system can add options to current parts and restore broken surfaces.

The Meltio M600 is appropriate with a variety of supplies together with aluminum and copper alloys, titanium, stainless steels, instrument steels, nickel, invar, and Inconel.

Spanish cement firm Cementos La Cruz has been introduced as the primary buyer to undertake Meltio’s new 3D printer. The agency has leveraged the M600 to 3D print a chrome steel nozzle for the manufacturing of extra sustainable, additively manufactured cement constructions.

Meltio’s new M600 wire-laser 3D printer

In keeping with Hoppe, the M600 seeks to advance Meltio’s mission to extend the adoption of metallic additive manufacturing. He believes that metallic 3D printing is but to attain its full potential, with the know-how nonetheless largely restricted to the low-volume manufacturing of high-value components.

The brand new 3D printer makes use of welding wire as its feedstock. These supplies are less expensive and safer to deal with than their powder-based counterparts, permitting the M600 to be extra simply built-in into current manufacturing workflows.

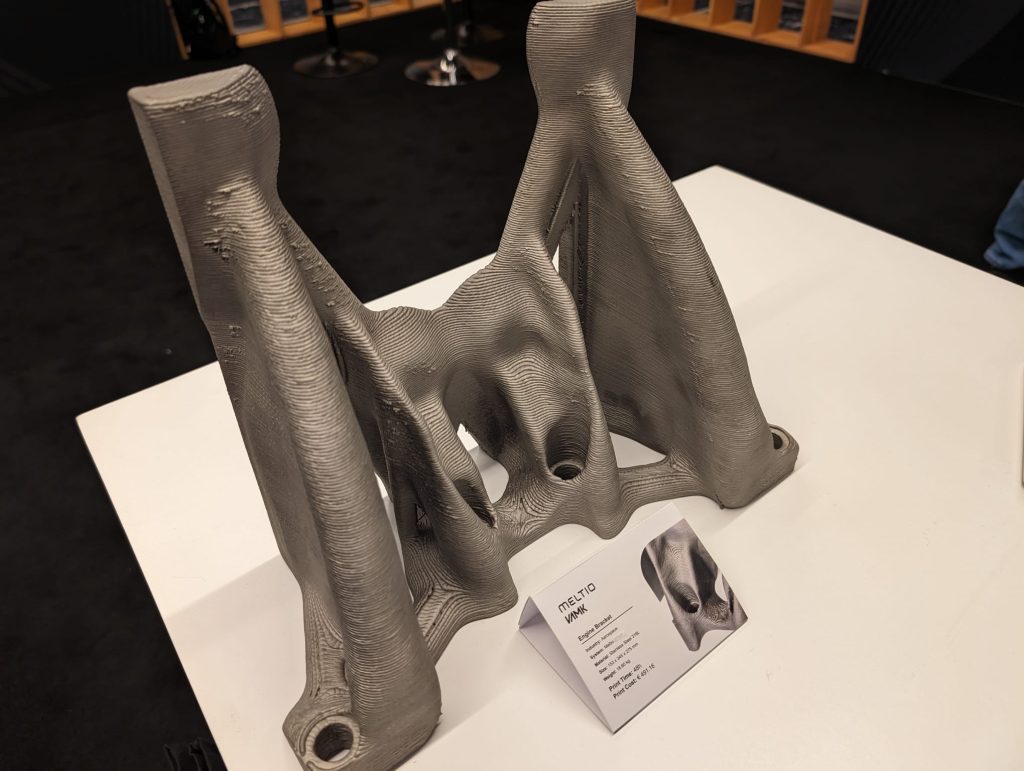

With a considerable construct quantity of 300 mm x 400 x 600 mm, Meltio claims that the wire-laser deposition strategy of its new 3D printer can produce high-quality components with comparable materials properties to these made with extra standard strategies.

The M600’s Blue Laser deposition head permits elevated 3D printing speeds with decrease vitality consumption, because of the lasers’ quick gentle wavelength. This provides greater absorption in comparison with most industrial lasers which emit near-infrared (NIR) gentle, whereas decreasing the carbon footprint of the manufacturing setup.

The Blue Lasers are notably properly suited to reflective supplies equivalent to copper and aluminum alloys, the place NIR lasers usually produce poor outcomes.

Meltio has labored to enhance vitality distribution and wire steerage, making certain that the deposition head is correctly aligned earlier than leaving the manufacturing facility ground and can’t be adjusted by the person. This reduces upkeep necessities and permits a extra constant output. Reliability can also be improved by the addition of sensors which monitor all the 3D printing course of.

The Meltio M600 has additionally been designed to combine into industrial environments that characteristic current CNC machines. With a built-in 3-axis contact probe, the system helps numerous sorts of workpieces. Subsequently, apart from 3D printing, Meltio’s new providing will also be used to restore or add options to current metallic components.

A highly-autonomous system, the M600 requires little or no operator interplay. Widespread inputs equivalent to handbook laser alignment have been eliminated altogether. Meltio states that it will improve the reliability and productiveness of the 3D printer, which has been designed for lights-out manufacturing. The Meltio Horizon toolpath era and slicing software program can also be appropriate with the M600, permitting 3D print jobs to be ready in a matter of minutes.

Meltio pronounces first M600 buyer

With the M600, Meltio has sought to design a 3D printer that may combine into any machine store and work alongside current CNC {hardware}.

The corporate claims that its new 3D printer provides notable worth by decreasing materials waste, slicing lead occasions, growing manufacturing flexibility, and finishing complicated 3D print jobs with minimal operator enter. That is stated to make the M600 well-suited to a variety of business verticals, together with automotive, aerospace, oil and fuel, mining, protection, and development.

The Meltio M600’s first publicly introduced buyer falls into the latter of those classes. Cementos La Cruz focuses on the manufacturing of cementitious supplies that possess a low carbon footprint. Centered on utilizing a round financial system, the corporate additionally develops concrete 3D printing know-how for development functions at its 3DLAB.

3D printing with concrete requires excessive management of fabric move. To realize this, the corporate has leveraged Meltio M600 to 3D print a nozzle that may produce high-quality layers of extruded concrete. In keeping with Meltio, the M600 has allowed Cementos La Cruz to design and produce components unattainable to provide with conventional manufacturing strategies.

Technical specs of the Meltio M600

Meltio is but to launch pricing info for its new M600 3D printer.

Dimension 1050 mm x 1150 mm x 1950 mmBuild Envelope 300 mm x 400 mm x 600 mmWeight 1000 kgMovement SystemServo Motor Linear axis with Absolute encoder on all axesFiltration System 3 stage particulate and chemical filtration included Environmental ControlControl O2 and humidity levelsLaser Kind 9x Direct Diode Lasers Laser Wavelength450 nmTotal Laser Strength1,000 WTotal axes 3Process Management Closed loop, laser and wire modulation Contact Probe Automated XYZ Contact Probe integration Enclosure Laser protected, absolutely inert Cooling Lively water cooled chiller included Wire Feedstock Diameter 0.7 mm – 1.2 mmWire Feedstock Spool BS300 or Exterior Wire Drum

What does the way forward for 3D printing maintain?

What near-term 3D printing developments have been highlighted by trade specialists?

Subscribe to the 3D Printing Trade e-newsletter to maintain updated with the newest 3D printing information. You can even observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a choice of out there roles and kickstart your profession.

Featured picture reveals a Giant glass mildew 3D printed with the brand new Meltio M600 on show at AMUG 2024. Photograph by 3D Printing Trade.

[ad_2]

Supply hyperlink