[ad_1]

Feb 29, 2024

(Nanowerk Information) Glass fiber-reinforced plastic (GFRP), a powerful and sturdy composite materials, is extensively utilized in every thing from plane components to windmill blades. But the very qualities that make it sturdy sufficient for use in so many various purposes make it troublesome to get rid of ⎯ consequently, most GFRP waste is buried in a landfill as soon as it reaches its finish of life.

Based on a research printed in Nature Sustainability (“Flash upcycling of waste glass fiber-reinforced plastics to silicon carbide”), Rice College researchers and collaborators have developed a brand new, energy-efficient upcycling technique to remodel glass fiber-reinforced plastic (GFRP) into silicon carbide, extensively utilized in semiconductors, sandpaper and different merchandise.

“GFRP is used to make very giant issues, and for probably the most half, we find yourself burying the wing buildings of airplanes or windmill blades from a wind turbine entire in a landfill,” mentioned James Tour, the T.T. and W.F. Chao Professor and professor of chemistry and of supplies science and nanoengineering. “Disposing of GFRP this fashion is simply unsustainable. And till now there was no good solution to recycle it.”

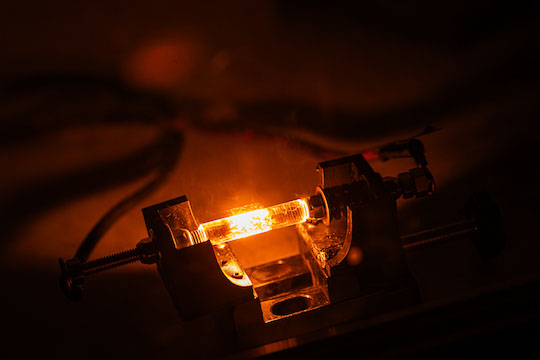

Flash Joule heating is a way that passes a present by means of a reasonably resistive materials to shortly warmth supplies to exceptionally excessive temperatures and rework them into different substances. (Photograph by Jeff Fitlow, Rice College)

With elevated stress from regulatory businesses to revise and enhance recycling practices for end-of-life autos, there’s a robust want for higher strategies to handle GFRP waste. Whereas some have tried to develop approaches utilizing incineration or solvolysis to eliminate GFRP, Yi Cheng, a postdoctoral analysis affiliate and Rice Academy Junior Fellow who works within the Tour lab, mentioned such processes are lower than very best as a result of they’re resource-intensive and end in environmental contamination.

“This materials has plastic on the floor of glass fiber, and incinerating the plastic can generate loads of poisonous gases,” Cheng mentioned. “Making an attempt to dissolve GFRP can also be problematic as it might generate loads of acid or base waste from the solvents. We needed to discover a extra environmentally pleasant solution to take care of this materials.”

Tour’s lab has already made headlines for creating new waste disposal and recycling purposes utilizing flash Joule heating, a way that passes a present by means of a reasonably resistive materials to shortly warmth it to exceptionally excessive temperatures and rework it into different substances. Tour mentioned when he realized of the problems concerned with GFRP disposal from colleagues on the Protection Superior Analysis Tasks Company, he thought that this sort of turbo-heating might rework GFRP into silicon carbide, extensively utilized in semiconductors and sandpaper.

“We already knew that if we warmth the combination of steel chloride and carbon by flash Joule heating, we might get steel carbide ⎯ and in a single demonstration, we made silicon carbide,” Tour mentioned. “So we had been in a position to leverage that work to give you a course of to remodel GFRP into silicon carbide.”

This new course of grinds up GFRP into a combination of plastic and carbon and entails including extra carbon, when crucial, to make the combination conductive. The researchers then apply excessive voltage to it utilizing two electrodes, bringing its temperature as much as 1,600-2,900 levels Celsius (2,912-5,252 Fahrenheit).

“That top temperature facilitates the transformation of the plastic and carbon to silicon carbide,” Tour defined. “We are able to make two totally different sorts of silicon carbide, which can be utilized for various purposes. In reality, one in all most of these silicon carbide exhibits superior capability and fee efficiency as battery anode materials.”

Whereas this preliminary research was a proof-of-concept take a look at on a bench scale within the laboratory, Tour and colleagues are already working with outdoors firms to scale up the method for wider use. The working prices to upcycle GFRP are lower than $0.05 per kilogram, less expensive than incineration or solvolysis ⎯ and extra environmentally pleasant.

It’s going to take time ⎯ and a few good engineering ⎯ to appropriately scale up this new flash upcycling technique, Tour mentioned. He mentioned he’s thrilled that his lab was in a position to develop a sustainable solution to rework GFRP trash into silicon carbide treasure.

“This GFRP is a waste product which normally leads to a landfill, and now you may flip it right into a usable product that may assist humankind,” he mentioned. “That is precisely the form of method we have to assist a round financial system. We have to discover methods to take waste merchandise from all kinds of various purposes and switch them into new merchandise.”

[ad_2]

Supply hyperlink