[ad_1]

Mar 12, 2024

(Nanowerk Highlight) Carbon nanotubes, with their exceptional electrical conductivity and spectacular mechanical energy, have lengthy been hailed as a revolutionary materials with the potential to rework industries. These one-dimensional nanostructures, consisting of cylindrical carbon molecules, can theoretically obtain electrical conductivity of as much as 106 S/cm and tensile energy exceeding 100 GPa. Such extraordinary properties make carbon nanotubes extremely promising constructing blocks for superior fiber supplies with unparalleled capabilities.

Regardless of their immense potential, the highway to translating the superlative properties of particular person carbon nanotubes into high-performance macroscopic fibers and yarns has been fraught with challenges. Researchers have grappled with the inherent issue of dispersing and aligning carbon nanotubes, which are likely to clump collectively on account of sturdy van der Waals forces. Furthermore, the excessive manufacturing prices, environmental and well being considerations, and restricted scalability of many synthesis strategies have hindered progress in the direction of widespread industrial adoption.

Over time, scientists have explored varied approaches to fabricating carbon nanotube yarns, together with moist spinning from liquid crystal dope or dispersions, dry spinning from vertically aligned nanotube arrays, and direct spinning from aerogels. Whereas every methodology has yielded incremental enhancements, reaching the total spectrum of fascinating attributes – resembling excessive packing density, glorious nanotube alignment, superior mechanical and electrical properties, and environment friendly large-scale manufacturing – has remained an elusive purpose.

Now, a crew of researchers from the Chinese language Academy of Tropical Agricultural Sciences and Deakin College in Australia has developed a groundbreaking moist spinning method that would lastly unlock the true potential of carbon nanotube yarns. As reported within the journal Superior Useful Supplies (“Moist Twisting in Spinning for Fast and Value-Efficient Fabrication of Superior Carbon Nanotube Yarns”), their speedy and steady “moist twisting” course of can produce extremely densified carbon nanotube yarns with exceptional properties in mere minutes.

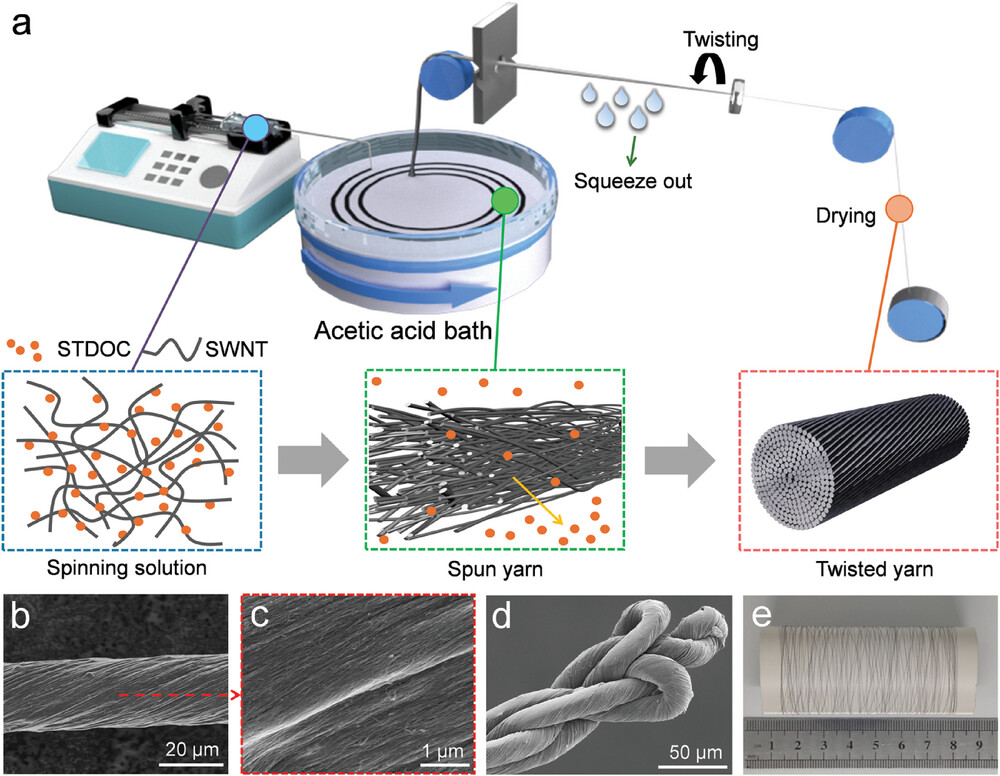

Moist-spinning and formation mechanism of neat CNT yarns. a) Schematic of the fabrication strategy of moist spun CNT yarns. The SWCNTs had been dispersed in water with STDOC as surfactants. The ensuing answer was then extruded into acetic acid (coagulation tub) by way of a syringe to provide steady CNT yarns. Lastly, the yarn was stretched and twisted to make it rapidly dehydrated after which collected by winding onto a spool. b) Scanning electron microscope (SEM) photos of the floor of the CNT yarns. c) The magnified SEM picture of the marked part in b) displaying the neat association of SWCNTs. d) Consultant SEM picture of tightly intertwined CNT yarns displaying nice flexibility and even look. e) Images of a single CNT yarn of over 20 m lengthy wrapped on a spool with out breaking. (Reprinted with permission by Wiley-VCH Verlag)

The important thing innovation lies within the mixture of strategic decisions at every stage of the spinning course of. First, the researchers successfully dispersed single-walled carbon nanotubes in water utilizing sodium taurodeoxycholate as a surfactant. This environmentally pleasant strategy ensures uniform dispersion whereas preserving the nanotubes’ size, an important issue for reaching optimum properties within the closing yarn.

Subsequent, the well-dispersed nanotube answer is extruded by way of a syringe into an acetic acid coagulation tub. The acetic acid not solely allows speedy solidification of the yarn but in addition successfully removes extra surfactant, yielding a pure and densely packed nanotube meeting. This considered number of the coagulation medium maintains the alignment of the nanotubes and prevents the introduction of impurities that would compromise the yarn’s conductivity.

The ultimate and most crucial step is the applying of a moist twisting remedy to the freshly fashioned nanotube yarn. By twisting the yarn whereas it’s nonetheless in a gel-like state, the researchers achieved a dramatic improve in packing density and nanotube alignment. This ingenious method effectively squeezes out residual solvent, leading to a compact yarn with a well-defined spiraling texture.

The influence of this moist twisting remedy on the properties of the carbon nanotube yarn is nothing wanting exceptional. In comparison with untreated yarns, the twisted yarns exhibit a tensile energy of as much as 600 MPa, representing an almost three-fold enchancment. The Younger’s modulus, a measure of the fabric’s stiffness, reaches a powerful 40 GPa. Concurrently, {the electrical} conductivity soars to 8990 S/cm, far surpassing earlier wet-spun carbon nanotube yarns produced with out using harsh acids.

These distinctive mechanical and electrical properties place the twisted carbon nanotube yarns on par with a few of the best-performing yarns fabricated utilizing extra advanced and dangerous strategies, resembling liquid crystal spinning with chlorosulfonic acid. Notably, the moist twisting strategy gives the benefits of simplicity, security, and effectivity, making it a extra enticing choice for large-scale manufacturing.

To show the sensible utility of their twisted carbon nanotube yarns, the researchers constructed a high-performance yarn heater. Remarkably, this heater showcases an ultrafast electrothermal response, reaching heating charges of over 1000 °C/s at a low working voltage of simply 5 V. Such speedy and environment friendly heating capabilities open up thrilling potentialities for purposes in thermal administration, wearable gadgets, and past.

Furthermore, the mechanical properties of the twisted carbon nanotube yarns exhibit glorious stability throughout a large temperature vary. Even when heated to 150 °C, the yarns retain their spectacular energy and modulus, an important issue for his or her dependable efficiency in real-world purposes.

Whereas this research represents a major development within the fabrication of high-performance carbon nanotube yarns, the researchers acknowledge that there’s nonetheless room for additional enchancment. The mechanical energy of the twisted yarns, though significantly enhanced in comparison with untreated yarns, stays decrease than some lately reported dry-spun carbon nanotube yarns. The authors recommend that optimizing the preliminary yarn alignment previous to twisting and exploring extra post-treatment strategies, resembling bonding molecular options to boost inter-nanotube interactions, may probably increase the mechanical properties even additional.

One other necessary consideration is the environmental and financial influence of this novel moist spinning course of. The usage of acetic acid because the coagulation tub gives a extra environmentally pleasant various to the tough acids generally employed in different strategies. Furthermore, the low value and glorious prospect of large-scale manufacturing related to moist spinning strategies make this strategy significantly enticing for industrial adoption. Because the demand for sustainable and cost-effective supplies grows, the event of inexperienced and scalable fabrication strategies turns into more and more essential.

The event of this speedy moist spinning and twisting course of for fabricating superior carbon nanotube yarns marks a major milestone within the subject of superior fiber supplies. By addressing the long-standing challenges of nanotube dispersion, alignment, and densification, whereas prioritizing scalability and environmental friendliness, this modern strategy paves the best way for the large-scale manufacturing and widespread adoption of high-performance carbon nanotube yarns.

Because the demand for light-weight, sturdy, and multifunctional supplies continues to develop throughout industries, from aerospace and automotive to wearable electronics and vitality storage, carbon nanotube yarns stand poised to revolutionize the panorama. With their unparalleled mixture of mechanical robustness, electrical conductivity, and thermal responsiveness, these yarns provide large potential for pushing the boundaries of fabric efficiency and enabling novel purposes.

The simplicity and effectivity of the moist spinning and twisting method developed by the Chinese language and Australian researchers convey us one step nearer to realizing the total promise of carbon nanotubes. As additional optimizations and scaled-up manufacturing strategies are explored, we will anticipate a future the place carbon nanotube yarns develop into a ubiquitous and indispensable materials, driving innovation and reworking industries worldwide. Nonetheless, continued analysis efforts are mandatory to completely unlock the potential of those exceptional supplies and overcome the remaining challenges on the trail to commercialization.

By

Michael

Berger

– Michael is writer of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Know-how,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Abilities and Instruments Making Know-how Invisible

Copyright ©

Nanowerk LLC

Nanowerk Publication

Get our Nanotechnology Highlight updates to your inbox!

Thanks!

You’ve gotten efficiently joined our subscriber record.

Develop into a Highlight visitor writer! Be a part of our giant and rising group of visitor contributors. Have you ever simply revealed a scientific paper or produce other thrilling developments to share with the nanotechnology neighborhood? Right here is how one can publish on nanowerk.com.

[ad_2]

Supply hyperlink