[ad_1]

Mar 01, 2024

(Nanowerk Information) Diamond is understood for its excellent thermal conductivity. This makes the fabric best for cooling digital parts with excessive energy densities, similar to these utilized in processors, semiconductor lasers or electrical autos. Researchers at Fraunhofer USA, an unbiased worldwide affiliate of the Fraunhofer-Gesellschaft, have succeeded in growing wafer-thin nanomembranes from artificial diamonds that may be built-in into digital parts, thereby decreasing the native warmth load by as much as ten occasions. This helps to enhance the street efficiency and repair life of electrical vehicles and considerably reduces battery charging time.

A rise in energy density and the ensuing greater warmth dissipation in digital parts require new supplies. Diamond is understood for its excessive thermal conductivity, which is 4 to 5 occasions greater than that of copper. Because of this, it’s a notably attention-grabbing materials with regards to cooling energy electronics in electrical transportation, photovoltaics or storage programs.

Till now, warmth sinks manufactured from copper or aluminum plates have elevated the heat-emitting floor of parts that produce warmth, thus stopping harm attributable to overheating.

Scientists at Fraunhofer USA Inc., Heart Midwest CMW in East Lansing in Michigan, an unbiased worldwide affiliate of the Fraunhofer-Gesellschaft, have now developed nanomembranes from artificial diamonds which might be thinner than a human hair.

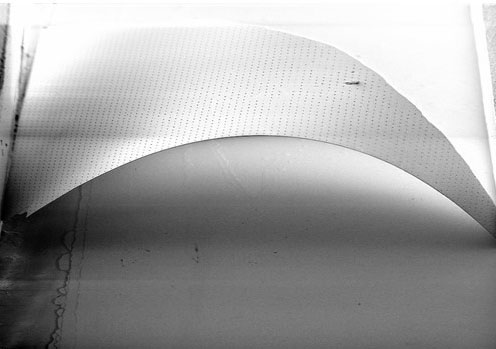

SEM picture of diamond nanomembrane that’s elastically bent beneath exterior impression of mechanical power. (Picture: Fraunhofer USA, Heart Midwest CMW)

The versatile materials might be built-in straight into digital parts to chill the facility electronics in electrical autos, which switch traction power from the battery to the electrical motor and convert the present from direct present to alternating present.

The versatile, electrically insulating nanomembranes developed by Fraunhofer USA have the potential to cut back the native warmth load of digital parts, similar to present regulators in electrical motors, by an element of ten. The power effectivity, service life and street efficiency of electrical vehicles are improved considerably because of this. One other benefit is the truth that, when used within the charging infrastructure, the diamond membranes contribute to charging speeds which might be 5 occasions greater.

Diamond membranes exchange the insulating intermediate layer

Usually talking, making use of a copper layer beneath the part improves the warmth circulate. Nevertheless, there may be an electrically insulating oxide or nitride layer between the copper and the part, which has poor thermal conductivity.

“We need to exchange this intermediate layer with our diamond nanomembrane, which is extraordinarily efficient at transferring warmth to the copper, as diamond might be processed into conductive paths,” says Dr. Matthias Mühle, head of the Diamond Applied sciences group on the Fraunhofer USA Heart Midwest CMW. “As our membrane is versatile and free-standing, it may be positioned wherever on the part or the copper or built-in straight into the cooling circuit.”

Mühle and his workforce obtain this by rising the polycrystalline diamond nanomembrane on a separate silicon wafer, then detaching it, turning it over and etching away the again of the diamond layer. This leads to a free-standing, easy diamond that may be heated at a low temperature of 80 levels Celsius and subsequently hooked up to the part.

“The warmth therapy robotically bonds the micrometer-thick membrane to the digital part. The diamond is then not free-standing however built-in into the system,” explains the researcher.

The nanomembrane might be produced on a wafer scale (4 inches and bigger), making it properly suited to industrial purposes. A patent has already been filed for the event. Software assessments with inverters and transformers in software fields similar to electrical transportation and telecommunications are attributable to begin this yr.

[ad_2]

Supply hyperlink