[ad_1]

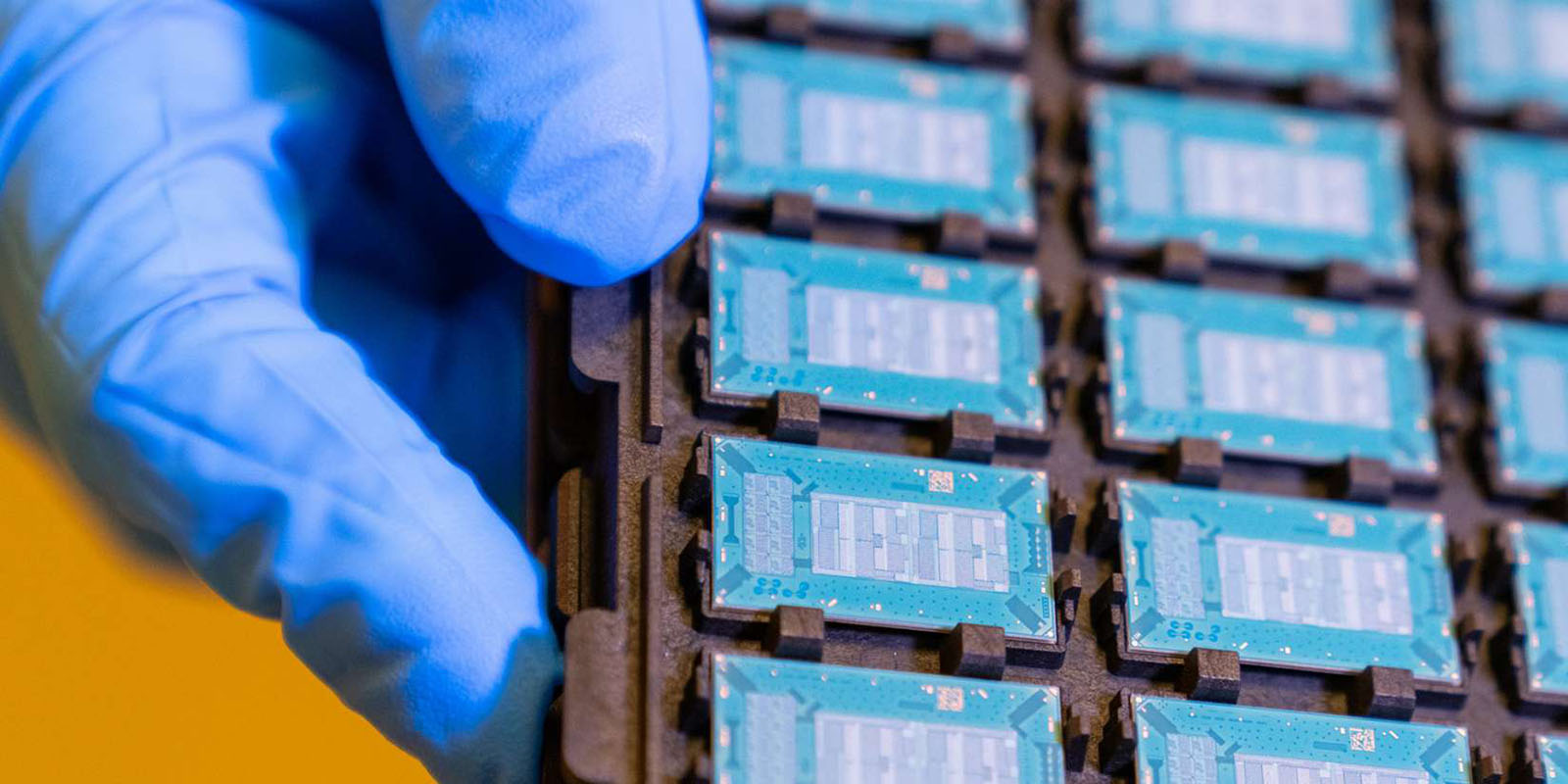

A brand new supply-chain report means that Apple is searching for to be an early participant in what some consider would be the subsequent large factor in chip improvement: printed circuit boards (PCBs) comprised of glass substrates.

Whereas that may not sound thrilling, it affords the prospect of a completely new method of mounting and packaging chips, which might supply a lot better thermal efficiency, permitting processors to run at most energy for longer durations …

Glass substrates can increase chip efficiency

Present PCBs are usually comprised of a mixture of fibreglass and resin beneath the copper and solder layers.

The fabric is delicate to warmth, which signifies that chip temperatures need to be rigorously managed by way of thermal throttling: lowering the efficiency of the chip when it will get too sizzling. This implies chips can solely maintain their most efficiency for restricted durations, earlier than falling again to slower speeds to maintain temperatures down.

Switching to glass would considerably enhance the temperatures the board might be subjected to, which in flip signifies that chips can run hotter, and due to this fact keep peak efficiency for longer.

Glass substrates are additionally ultra-flat, permitting for extra exact engraving, which permits elements to be positioned nearer collectively, rising the density of circuits inside any given measurement.

Intel at present holds the lead on this subject, however different firms are working laborious to catch up.

Apple in dialogue with suppliers

Digitimes experiences that Samsung is now engaged on this know-how, and that Apple is in dialogue with a number of unnamed suppliers – with Samsung sure to be amongst them.

Subsidiaries of the Samsung Group will collaborate to put money into the analysis and improvement of Glass Core Substrates (GCS) to expedite their commercialization, aiming to rival Intel, which has taken an early lead on this sector […]

Apple is reportedly in discussions with a number of firms to plan a method for incorporating glass substrates into digital gadgets. The adoption of glass substrates by Apple sooner or later is anticipated to considerably broaden the scope of software areas.

Sources inside the semiconductor trade indicated that cup substrates could grow to be a brand new subject for completion amongst nations, attracting participation from international IT gadget producers and semiconductor gamers along with substrate producers.

Samsung is well-placed to work on this, as lots of the methods utilized in manufacturing superior, multilayered shows are additionally relevant to creating glass substrate PCBs.

Probably the following large factor, however with challenges

The rationale some consider that cup substrates would be the subsequent large factor in chip improvement is that almost all progress thus far has been achieved by way of ever-smaller processes. Apple at present leads the best way with the 3nm chip within the A17 Professional powering the iPhone 15 Professional fashions, with plans for 2nm after which 1.4nm.

Every successive course of technology is more durable and more durable to realize, with final bodily limits to simply how small we will go. With doubts as to how lengthy Moore’s Legislation will stay in impact, some consider that new supplies maintain the important thing to sustaining the tempo of improvement as we start reaching the bounds of course of measurement.

Nevertheless, there are large challenges forward, as SemiEngineering explains.

“Take into consideration glass as a way to get interconnect density similar to what you’d get with silicon interposers,” says Rahul Manepalli, fellow and director of substrate TD module engineering at Intel. “A glass substrate provides you that functionality, nevertheless it comes with very difficult integration and interface engineering issues that we have now to resolve.”

A few of these challenges embrace fragility, an absence of adhesion to metallic wires, and difficulties in attaining uniform by way of fill, which is essential for constant electrical efficiency. As well as, glass presents distinctive challenges for inspection and measurement, because of its excessive stage of transparency and differing reflective indices in comparison with silicon. Many measurement methods that work on opaque or semi-transparent supplies are much less efficient on glass. As an example, optical metrology programs that depend on reflectivity to gauge distance and depth should adapt to glass’ translucency, which may trigger sign distortion or loss, compromising measurement accuracy.

“All of those applied sciences assume sure physics,” says John Hoffman, laptop imaginative and prescient engineering supervisor at Nordson Take a look at & Inspection. “Whenever you begin altering substrates, will the physics nonetheless work? And may you recuperate? A variety of our algorithms make sure assumptions in regards to the physics. Do these algorithms nonetheless work, or do we have now to provide you with model new algorithms as a result of the physics has modified?”

Picture: Intel

FTC: We use revenue incomes auto affiliate hyperlinks. Extra.

[ad_2]

Supply hyperlink