[ad_1]

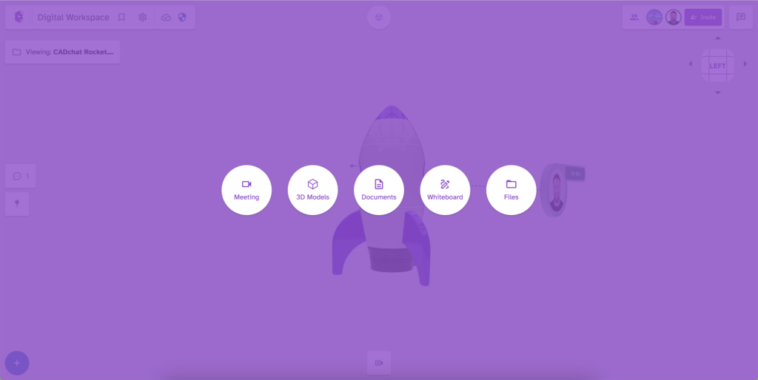

Graham Bredemeyer, the founding father of modern additive manufacturing (AM) agency Collider, is again on the startup scene, this time with a platform for CAD-related video conferencing referred to as CADchat. The corporate proposes CADchat as a device that contains the entire disparate options of Zoom, Slack, and Dropbox mixed with CAD viewing and annotating. From the appears to be like of it, CADchat may really be a game-changer for collaborative product improvement.

Although the COVID-19 pandemic drove numerous workplace staff to make use of digital conferencing applications like Zoom and Microsoft Groups, these of us who’ve relied on such instruments know that they’re considerably missing, significantly in relation to 2D and 3D design. Exterior of the usually buggy interfaces, file sharing and collaboration are primarily restricted to screensharing. In the event you’ve obtained some doc you wish to current to a coworker, it means sharing your display and scrolling round to get them on top of things.

CADchat appears to construct considerably on this functionality, and it does so with 3D modeling options. Slightly than merely share a display, a person is ready to share a 3D mannequin interface the place anybody can annotate, chat, and share information. The mannequin round which everybody pow-wows may be rotated and commented upon by anybody within the digital assembly. As a result of the CAD file is hosted within the cloud, there doesn’t seem like any lag when manipulating the mannequin just about.

On prime of the capabilities associated to 3D modeling, customers can even share and collaborate on 2D information, reminiscent of 2D CAD drawings and even Excel spreadsheets, or bounce concepts off of each other utilizing a digital whiteboard. The platform additionally acts as a file sharing hub so {that a} undertaking can have a single supply of reality for the entire vital paperwork.

Maybe most necessary of all is that each one of this exercise persists even after a gathering has ended, together with mannequin annotations, the messenger field, the whiteboard, and the information. On this method, not solely does CADchat mix Zoom, Slack, Dropbox, and a 3D mannequin viewer, however it additionally doesn’t go away as soon as the decision is over. You’ll be able to return to the assembly and revisit your colleague’s notes and doodles even when everyone seems to be offline.

“Product improvement doesn’t finish when the assembly does, and neither ought to the instruments we use. With CADchat, we’re thrilled to supply a platform that not solely helps real-time collaboration but in addition enriches the continuity of teamwork. Our digital workspaces be certain that all the pieces from 3D fashions to vital suggestions stays accessible and interactive lengthy after the calls have ended,” mentioned Graham Bredemeyer, CEO of CADchat. “Our purpose is to redefine collaboration by sustaining the integrity and continuity of each assembly. Consider it as a everlasting, digital convention room, the place your whole project-related discussions, selections, and paperwork are only a click on away.”

The entire options, even with out the CAD facet, appear highly effective sufficient for digital conferences, however as a result of it contains the power to share 3D fashions, the platform looks like a lacking piece of the puzzle for engineers and designers. Practically each CAD firm has been making an attempt to create a unified platform to attach their disparate apps, however none appears to have totally succeeded. The aesthetic of the platform mirrors the simplicity and streamlined nature of Autodesk instruments, so one wonders if an integration with Fusion could also be within the works. Nevertheless, CADchat appears to be like like it will be equally at dwelling within the 3DEXPERIENCE from Dassault.

Such an integration doesn’t appear unlikely, given the caliber of purchasers the corporate has up to now. CADchat has already listed GE Vernova as a buyer. The energy-focused spin-off of the manufacturing large is already poised to impression the transition to sustainable gasoline sources. On this case, nevertheless, GE claims to have “scale back[d] half and tooling improvement cycle occasions from two to a few months to as little as one to 2 weeks.” This enchancment of over 90% in effectivity was achieved with none new {hardware}.

It’s fascinating to notice how this product improvement effectivity parallels the kinds of enhancements made doable by 3D printing a number of design iterations. Maybe, the parallel emerges from Bredemeyer’s historical past in AM, through which he developed a singular technique for 3D printing sacrificial tooling that was full of injection molding plastic multi function manufacturing course of. One other fascinating factor to the story is that, after creating such a novel {hardware} for AM, Bredemeyer is now engaged on software program. Maybe the decrease overhead of working a software program startup will assist support in CADchat’s success shifting ahead.

These within the digital workspace platform can join a free trial right here.

[ad_2]

Supply hyperlink