[ad_1]

Massachusetts-based industrial 3D printer producer Desktop Metallic and German chemical compounds firm Evonik have introduced a partnership on photopolymer and supplies growth.

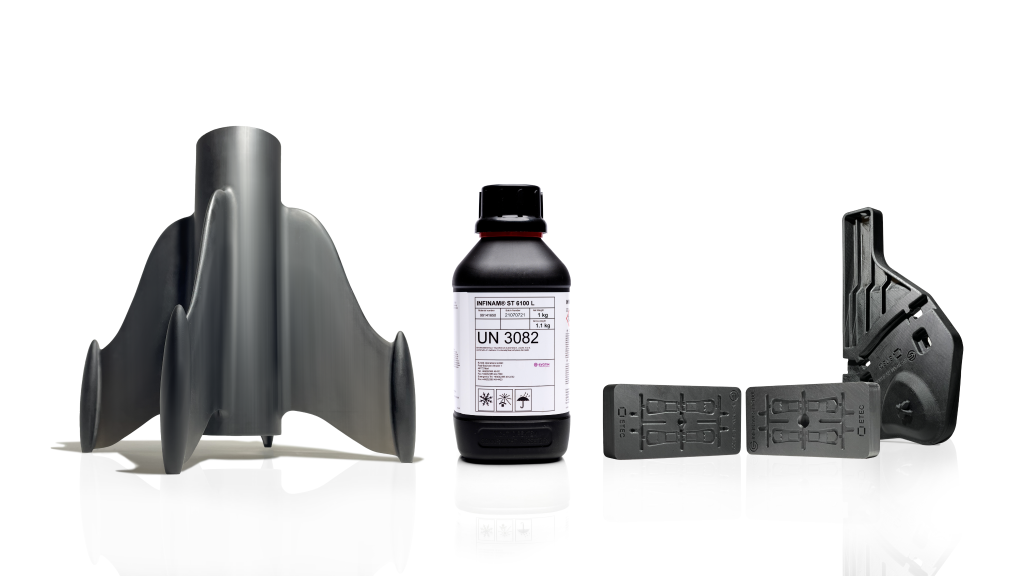

This partnership goals to qualify Evonik’s INFINAM ST 6100 L materials on Desktop Metallic’s ETEC Xtreme 8K and Professional XL printers. INFINAM ST 6100 L presents properties supreme for 3D printing molds, fashions, tooling, and end-use elements in aerospace, automotive, and electronics. When paired with the ETEC Professional XL’s 65 μm decision, elements printed in INFINAM ST 6100 can precisely obtain intricate particulars and fantastic geometries. Moreover, elements created with this materials can seamlessly bear machining, sprucing, and different post-processing processes.

“Collaboration with prospects and companions is a crucial driver of innovation for us,” stated Vitor Lavini, head of Evonik’s photopolymer market phase within the firm’s Additive Manufacturing Innovation Development Subject. “The validation of ST 6100 L on Desktop Metallic’s printers – particularly the ETEC Xtreme 8K – suits with Evonik’s imaginative and prescient that bigger and sooner DLP printers will improve productiveness, considerably cut back prices per half, and allow sequence manufacturing in the long term.”

A mix of velocity and energy for industrial 3D printing

As said by the corporate, Evonik’s INFINAM ST 6100 L presents an final tensile energy (UTS) of 90 MPa, flexural stress of 135 MPa, and a warmth deflection temperature (HDT) of 120°C. It additionally boasts distinctive precision, floor end, and resilience to numerous chemical compounds and ultraviolet (UV) degradation. Desktop Metallic’s ETEC model for polymer 3D printing leads in Digital Gentle Processing (DLP) {hardware} and presents a meticulously curated portfolio of the best AM supplies obtainable worldwide, says the corporate.

As an industrial-grade DLP printer for high-volume manufacturing, the ETEC Xtreme 8K has a big 66-liter construct quantity and two overhead projectors. With dimensions of 450 × 371 x 399 mm (17.72 x 14.61 x 15.71 in), the ETEC Xtreme 8K presents an expansive construct quantity. It’s value noting that this method is manufactured at Desktop Metallic’s Polymer Heart of Excellence situated in Richardson, Texas.

With a price ticket beneath $40,000, the ETEC Professional XL is positioned as a premium DLP printer, says Desktop Metallic. It options 385 nm wavelength expertise, 5mW/cm2 energy, and Hyperprint closed-loop printing, all contributing to superior outcomes achieved at excessive printing speeds. Providing a construct quantity of 249.1 x 140.1 x 165.1 mm (9.8 x 5.5 x 6.5 in), the ETEC Professional XL is designed to satisfy various additive manufacturing wants.

Parts produced utilizing Evonik’s INFINAM ST 6100 L materials on the ETEC Xtreme 8K can be showcased on the Additive Manufacturing Customers Group (AMUG) 2024 Convention in Chicago, from March 10 to 14, on the Evonik sales space P12, Salon D.

Materials growth alliances

The collaboration between Desktop Metallic and Evonik’s is the most recent in an extended listing of fabric growth efforts. Final month, Quantica partnered with ImageXpert, integrating NoveJet JetPack with JetXpert for materials jetting testing. This collaboration goals to democratize NovoJet printhead expertise, to advance digital manufacturing and materials growth. Tailor-made for ImageXpert’s Dropwatcher, JetPack analyzes droplet traits, enabling automated testing.

With half-micron decision and eight million fps publicity time, Dropwatcher presents exact measurements. Quantica goals to increase its inkjet printing tech to electronics, masking conductive tracks, insulation layers, solder pastes, and extra. Finally, the partnership goals to transition conventional analog manufacturing processes into the digital house, selling materials growth and inkjet 3D printing capabilities.

Elsewhere, Mechnano and Bomar launched the T50B masterbatch designed for 3D printing. Leveraging Mechnano’s D’Func expertise, T50B focuses on enhancing mechanical properties and sustaining constant electrical efficiency in AM resins. With elevated CNT focus and minimal viscosity, it simply incorporates into resin formulations, suitable with numerous resin sorts and printing applied sciences. T50B permits fine-tuning of electrical resistivity and improves mechanical traits, promising enhanced element efficiency.

What 3D printing developments do the business leaders anticipate this yr?

What does the Way forward for 3D printing maintain for the following 10 years?

To remain updated with the most recent 3D printing information, don’t overlook to subscribe to the 3D Printing Trade e-newsletter or comply with us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you on the lookout for a job within the additive manufacturing business? Go to 3D Printing Jobs for a choice of roles within the business.

Featured picture exhibits 3D printed elements printed on ETEC {hardware} from Desktop Metallic utilizing Evonik INFINAM® ST 6100 L. Picture by way of Evonik.

[ad_2]

Supply hyperlink