[ad_1]

Steel 3D printing firm Seurat Applied sciences has certified 6K Additive’s 316L chrome steel powder to be used on Seurat’s Space Printing platform, to reinforce sustainability within the additive manufacturing sector.

Seurat Applied sciences’ pilot manufacturing facility in Better Boston is about to function solely on clear power, aiming to provide over 25 tons of steel elements annually. In the meantime, 6K Additive stands out for its notably decrease power consumption and diminished carbon emissions in manufacturing. In accordance with the corporate, this achievement is attributed to its use of sustainable feedstock sources, implementation of a extremely environment friendly microwave plasma course of, and supply of yields exceeding 90%. In comparison with typical atomization strategies, 6K Additive’s strategy demonstrates a considerable discount in environmental affect.

“Our means to leverage machining scrap, used powders, and different revert feedstock for all kinds of steel powders units us aside from every other powder provider within the business with regard to sustainability. Backed by the effectivity of our UniMelt course of, it’s clear why 6K Additive is taken into account a frontrunner in sustainable powder manufacturing for AM,” mentioned, Nick Pflugh, Chief Business Officer for 6K Additive. “Prospects now have a really compelling cause to work with Seurat for half manufacturing, powered by the world’s most sustainably sourced powder from 6K Additive.”

6K Additive’s contributions to eco-friendly additive manufacturing

Seurat makes use of 100% inexperienced power to innovate and localize manufacturing with its Space Printing know-how, developed at Lawrence Livermore Nationwide Laboratory. This steel AM know-how facilitates high-precision, high-volume, and decarbonized manufacturing processes. Seurat estimates that its implementation might straight mitigate as much as 100 million tons of CO2 by 2030.

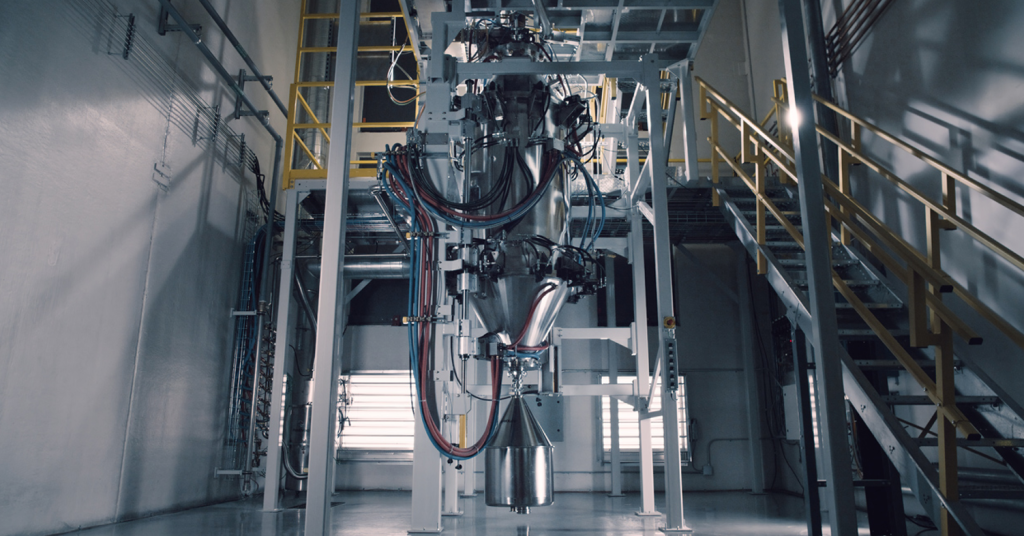

6K Additive’s product portfolio features a vary of premium powders, equivalent to nickel, titanium, copper, chrome steel, aluminum alloys, and refractory metals like tungsten, niobium, and rhenium. The corporate’s proprietary UniMelt system is highlighted for its distinctive capabilities, together with exact plasma management, minimal contamination, superior efficiency, and excessive manufacturing throughput.

Again in 2023, 6K Additive and Fraunhofer ILT collaborated on a life cycle evaluation (LCA) for additive manufacturing, aiming to make clear its environmental affect. Using sustainably produced Ni718 powder from 6K Additive, the examine assessed carbon emissions from materials by post-processing on a laser powder mattress fusion (LPBF) machine.

Early findings offered at Formnext 2022 revealed important reductions in power and carbon emissions with 6K’s UniMelt platform. The examine emphasised the significance of evaluating the whole additive manufacturing course of for sustainability, addressing market calls for for carbon neutrality options.

“Our partnership with 6K Additive is helpful for Seurat on a number of fronts,” added, Ben Fotovvati, Additive Manufacturing Course of Engineer at Seurat Applied sciences. “Not solely are we partnering with a provider that may meet our powder high quality necessities, however we’re additionally teaming with a frontrunner in sustainably sourced supplies, which aligns completely with our decarbonization mission.”

A greener future throughout the AM sector

Sustainability is paramount within the 3D printing sector to mitigate environmental affect, preserve sources, and foster a extra accountable strategy to manufacturing. Because the business continues to evolve, integrating sustainable practices shall be important for its long-term viability and development. This 12 months alone noticed two entities aiming to extend the sustainability of AM processes.

Supported by the Nationwide Manufacturing Institute Scotland (NMIS) with £1 million, the AM-BATS mission aids over 100 Scottish SMEs in adopting industrial additive manufacturing. NMIS has guided corporations throughout sectors to combine 3D printing, aiming to unlock new alternatives and fostering a shift in direction of sustainable manufacturing in Scotland’s industries.

Over three years, NMIS assists in feasibility assessments, supplies coaching, and evaluates sustainability advantages. The initiative, aiding 36 ventures, spans industries like EVs, meals, sports activities, and medication. Firms leverage additive manufacturing for enhanced merchandise, citing sooner improvement, sustainability, and effectivity. Examples embody medical gadgets by Confidence Plus and eco-friendly trend by ROCIO.

Initially of the 12 months, the winners of the Environmental Additive Analysis for Tomorrow’s Habitat (EARTH) mission obtained a $1.2 million grant from America Makes. Carried out in partnership with the Nationwide Heart for Protection Manufacturing and Machining (NCDMM), this mission focuses on advancing sustainable additive manufacturing practices, significantly when it comes to recycling and reutilization of 3D printing supplies. Chosen to advance this mission, the successful initiatives will make the most of the funding to discover and validate additive manufacturing designs and supplies that align with sustainability standards.

What 3D printing developments do the business leaders anticipate this 12 months?

What does the Way forward for 3D printing maintain for the subsequent 10 years?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Trade publication or observe us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you on the lookout for a job within the additive manufacturing business? Go to 3D Printing Jobs for a choice of roles within the business.

Featured picture exhibits 6K’s UniMelt plasma manufacturing system is uniquely able to changing high-value steel scrap of quite a few varieties into high-performance steel powders for additive manufacturing. Photograph by way of 6K Additive.

[ad_2]

Supply hyperlink