[ad_1]

Researchers from the Massachusetts Institute of Know-how (MIT) have efficiently 3D printed tender, magnetic-cored solenoids which are extra highly effective than these made with different strategies.

These electromagnets incorporate a coil of wire wrapped round a magnetic core and play a key position in lots of digital gadgets comparable to dialysis machines and respirators.

Having modified a commercially accessible multi-material 3D printer, the researchers had been in a position to fabricate the solenoids in a single step. It’s hoped that this strategy will improve the accessibility of key digital gadgets for individuals with restricted assets, or these residing in distant areas.

“There is no such thing as a motive to make succesful {hardware} in only some facilities of producing when the necessity is world. As an alternative of making an attempt to ship {hardware} everywhere in the world, can we empower individuals in distant locations to make it themselves?” said Luis Fernando Velásquez-García, senior writer of the MIT examine which was lately printed within the journal Digital and Bodily Prototyping.

“Additive manufacturing can play an amazing position when it comes to democratizing these applied sciences.”

These 3D printing capabilities might additionally play a key position in manufacturing digital gadgets throughout future house missions. Reasonably than sending alternative parts from Earth, comparable 3D printers may very well be used to manufacture the elements the place they’re wanted, saving money and time.

Producing solenoids with multi-material 3D printing

Additive manufacturing can be utilized to supply solenoids of virtually any form or dimension. Nevertheless, producing these gadgets requires the exact mixture of a number of supplies.

To provide their solenoids, the MIT crew utilized a dielectric materials which serves as an insulator, a conductive materials that kinds {the electrical} coil, and two tender magnetic supplies for the core – one based mostly on a biodegradable thermoplastic and the opposite on nylon.

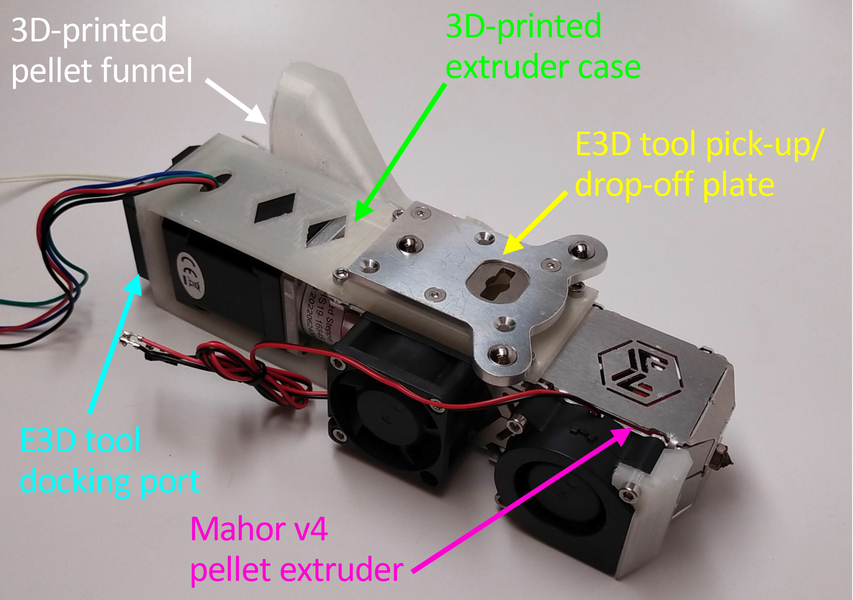

Combining these supplies poses challenges for standard, single-nozzle 3D printers which might solely extrude a single materials at a time. Subsequently, the MIT researchers leveraged a 3D printer with 4 extruders, every devoted to a special materials.

One of many nozzles was modified to extrude pellets somewhat than filaments. This enabled the crew to include a tender magnetic nylon 12 materials studded with metallic micro-particles, which was not accessible in filament type. Further air flow was additionally added to assist cool the conductive materials, stopping the nozzle from clogging throughout extrusion.

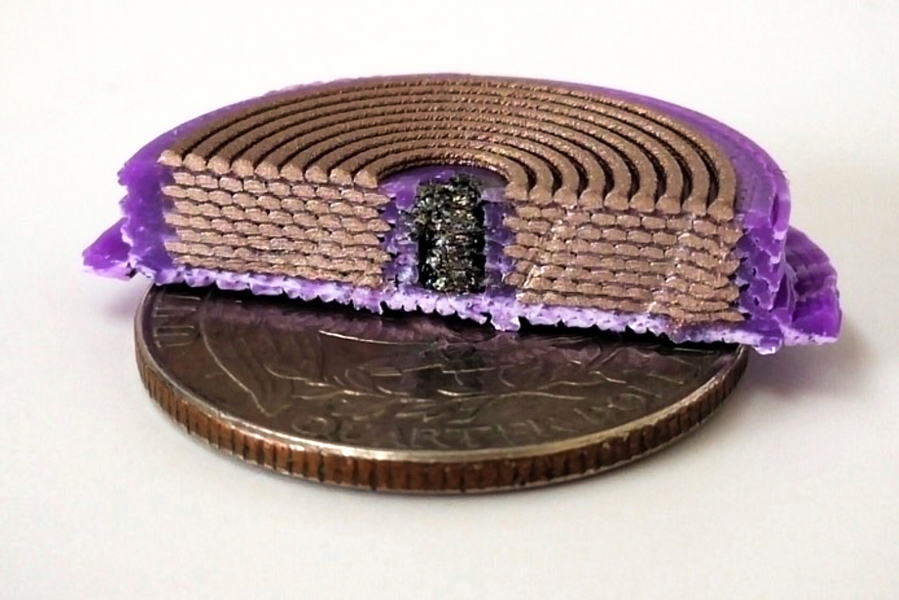

Costing round $4,000, the crew’s modified 3D printer can produce full solenoids consisting of eight layers, with coils and insulating materials exactly positioned across the magnetic core. Because of the precision supplied by this strategy, the crew efficiently produced gadgets 33% smaller than these made with different 3D printing strategies.

Incorporating extra coils inside a smaller space can enhance amplification. Subsequently, MIT’s solenoids are able to withstanding twice as a lot electrical present and producing a magnetic area thrice stronger than these made with different 3D printers.

By fabricating every machine as a single piece, the researchers additionally eradicated the potential for defects that may very well be launched throughout post-processing and meeting. This may additionally scale back manufacturing prices and minimize manufacturing waste.

Seeking to the longer term, the researchers will subsequent work to reinforce the efficiency of their 3D printed solenoids, which might embrace utilizing supplies with higher properties. Further modifications that would extra exactly management deposition temperature are additionally being thought-about, with the hope of decreasing defects.

Developments in 3D printed electronics

Using additive manufacturing rising know-how within the manufacturing of digital gadgets. Again in 2022, researchers from the Tallinn College of Know-how and the Estonian College of Life Sciences investigated using 3D printing for the manufacturing of sentimental magnetic cores utilized in electrical gadgets.

The analysis crew’s complete laser-based steel 3D printing workflow can reportedly produce tender magnetic composites with superior magnetic properties. The researchers argued that this strategy overcomes key challenges related to preserving core effectivity. As such, the strategy presents worth for varied electrical programs comparable to electromagnets, transformers, electrical motors, turbines, inductors, and different magnetic assemblies.

Elsewhere, Scientists from Nanyang Technological College Singapore (NTU Singapore) and the Singapore Centre for 3D Printing (SC3DP) have developed a multi-material 3D printer for the manufacturing of wearable electronics.

Produced in collaboration with Japanese electronics agency Panasonic, the 3D printer incorporates multi-wavelength, high-powered lasers that may convert frequent carbon-based supplies into a brand new sort of extremely porous graphene. This method seeks to fulfill elevated market demand for versatile and wearable digital gadgets that may be bent, twisted, and conformed to varied surfaces.

The companions, who’ve been engaged on this mission since 2016, consider that this 3D printer might revolutionize additive manufacturing, opening new potentialities for the manufacturing of gadgets with unmatched performance and adaptability.

What does the way forward for 3D printing maintain?

What near-term 3D printing developments have been highlighted by trade specialists?

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the newest 3D printing information. You may also observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing trade? Go to 3D Printing Jobs to view a collection of accessible roles and kickstart your profession.

Featured picture exhibits a 3D printed, multi-material solenoid. Picture by way of the Massachusetts Institute of Know-how.

[ad_2]

Supply hyperlink