[ad_1]

Mar 12, 2024

(Nanowerk Information) 3D printing has modified the world.

It’s allowed the aerospace, medical, automotive, manufacturing and lots of different industries to customise elements and prototypes in methods they by no means might earlier than. It has drastically elevated flexibility and value effectiveness whereas lowering waste and manufacturing time. However many 3D-printed supplies aren’t the strongest.

A group of chemists and supplies scientists at Sandia Nationwide Laboratories hopes to alter that.

They’ve developed a brand new printing course of that prints stronger nonmetallic supplies in document time, 5 instances sooner than conventional 3D printing.

“It opens up an entire new world of what you may construct and what 3D supplies can be utilized for,” stated Samuel Leguizamon, supplies scientist.

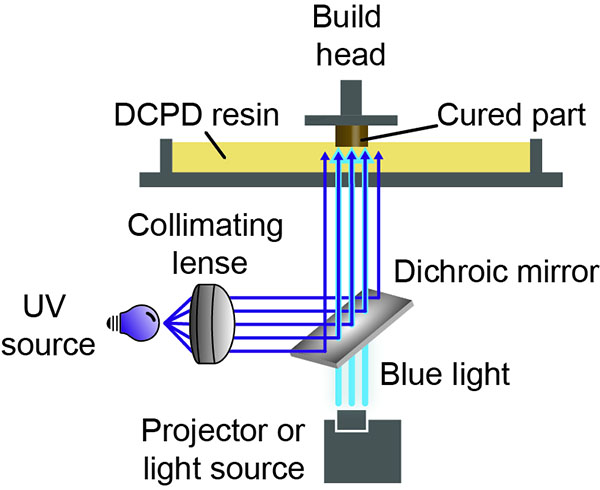

He led the group that developed SWOMP, which stands for Selective Twin-Wavelength Olefin Metathesis 3D-Printing. As indicated by its title, it makes use of dual-wavelength mild, in contrast to the normal printing course of.

SWOMP, or Selective Twin-Wavelength Olefin Metathesis 3D -Printing, makes use of two wavelengths of sunshine concurrently to alter the way in which sure supplies are 3D- printed. (Graphic: Samuel Leguizamon)

How 3D printing works

Historically, vat 3D printing is completed by irradiating a vat of photosensitive liquid resin in a desired sample.

Because the resin is uncovered to mild from beneath the vat, the resin cures and hardens right into a polymer layer. The cured polymer is then lifted, and a brand new sample is projected beneath to remedy subsequent layers.

One problem: Because the polymer cures, it adheres to the earlier layer and to the underside of the vat. After every layer, the cured polymer have to be slowly peeled from the vat to forestall harm, considerably slowing down the 3D printing course of.

Fellow creator Leah Appelhans stated it’s sort of like baking cookies.

“After you bake the cookies, you need to allow them to cool,” she stated. “For those who have been to attempt to peel the nice and cozy cookie off the cookie sheet, it’s squishy and it breaks aside. The identical factor would occur with a 3D printer in the event you tried to rapidly print every layer. Your work would get deformed.”

Leguizamon, Appelhans, former Sandia worker Jeff Foster and polymer scientist Alex Commisso got here up with a method to cool the “cookies” faster.

Your browser doesn’t assist the video tag.

UV and blue mild

The secret is combining two lights. On this case, ultraviolet and blue mild.

The group took inspiration from a method generally known as steady liquid interface printing together with a printing strategy utilizing dual-wavelength mild for acrylic-based polymerizations.

With it, they created SWOMP.

“You’re nonetheless printing layer by layer, however you might be utilizing a second wavelength of sunshine to forestall polymerization on the backside of the vat. So it doesn’t adhere to the underside,” Leguizamon stated. “Meaning you may raise the cured polymer half extra rapidly and velocity up the printing course of considerably.”

Making 3D supplies stronger

However this new course of isn’t nearly effectivity. It’s about making 3D-printed supplies stronger and extra versatile. Most vat polymerization printed supplies are acrylic-based, not the strongest materials.

“It’s actually arduous to make use of these supplies in issues like plane and area and aerospace and automotive; they’re very harsh environments,” Sandia licensing govt Bob Sleeper stated.

This group turned to the fabric dicyclopentadiene, which is often used within the manufacturing of paints, varnishes and flame retardants for plastics. They have been in a position to develop a method to polymerize it extra quickly with mild in order that it may be used extra effectively in 3D printing.

“We modified constructing blocks of the supplies from acrylic-based to olefin-based,” Leguizamon stated. “Which lets us print supplies which might be rather a lot more durable.”

“That’s the fantastic thing about what they’re doing,” Sleeper stated. “You’ve very high-quality plastic elements which might be made very exactly through the use of some mild in a really novel method.”

Opening a brand new world of 3D printing

This group hopes their new printing course of will open the world of 3D printing.

Whereas the mission was initially funded via a fast three-month Exploratory Categorical program, it’s now funded by a Sandia expertise maturation program.

“What we are attempting to do is construct the toolbox of supplies obtainable,” Appelhans stated. “We would like designers, researchers, engineers to have the ability to choose the kind of materials they wish to use.”

In the future, they hope to see these 3D-printed elements in rockets, engines, batteries and perhaps even in fusion purposes. Leguizamon stated they’re already speaking with researchers at Lawrence Livermore Nationwide Laboratory to discover purposes.

“It seems that monomers are already utilized in fusion elements,” he stated. “You don’t often consider a polymer utilized in fusion, but it surely’s actually cool and thrilling potential.”

The group additionally sees a world the place 3D printing will be performed extra simply in distant areas.

“We’re taking a look at areas the place equipment and elements will not be available; like in area, on the moon or within the Center East at a U.S. navy base,” Sleeper stated. “You possibly can deliver with you some light-weight supplies and make no matter you want on the spot.”

Leguizamon, who grew up within the small city of Wagener, South Carolina, can be considering of purposes that would assist nearer to house.

“I’ve horses,” he stated. “I grew up in a rural space, my dad was a farrier, so I’m considering of the way to make horseshoes for racehorses. They need to be impact-resistant, however by altering the fabric properties, stress will be higher unfold out and affect in the precise area on the hoof. You might consider it as insoles for horses.”

The chances are limitless.

“I believe what attracted me to chemistry within the first place is the potential to make one thing that has by no means existed earlier than,” Appelhans stated. “The enjoyable factor about 3D printing is that you just apply that chemical data to one thing that has a really concrete consequence. One thing you may see and maintain in your fingers.”

[ad_2]

Supply hyperlink