[ad_1]

Mar 18, 2024

(Nanowerk Highlight) The arrival of wearable know-how has introduced with it a urgent want for power storage options that may hold tempo with the pliability and stretchability of soppy digital gadgets. Standard inflexible batteries and supercapacitors have confirmed insufficient for seamless integration into wearables that should conform to the human physique and face up to the pressure of each day use. This mismatch between power storage and machine flexibility has hindered progress in fields comparable to well being monitoring, good textiles, and biomedical implants.

Micro-supercapacitors (MSCs) have emerged as a promising candidate for deformable power storage, due to their high-power density, fast charging, and lengthy cycle life. Nonetheless, creating the intricate interdigitated electrode patterns vital for high-performance MSCs utilizing supplies that may endure repeated stretching and twisting has confirmed difficult. Whereas researchers have made strides in enhancing flexibility by way of ingenious patterning and elastic substrates, many approaches require advanced fabrication and nonetheless fail below excessive deformation.

Now, a collaborative analysis effort led by Dr. Chanwoo Yang from the Korea Institute of Industrial Expertise and Professor Jin Kon Kim from Pohang College of Science and Expertise, has yielded a possible resolution. Of their paper revealed in npj Versatile Electronics (“Deformable micro-supercapacitor fabricated through laser ablation patterning of Graphene/liquid steel”), the group particulars the fabrication of extremely deformable graphene primarily based MSCs utilizing liquid steel present collectors on an elastic polymer substrate.

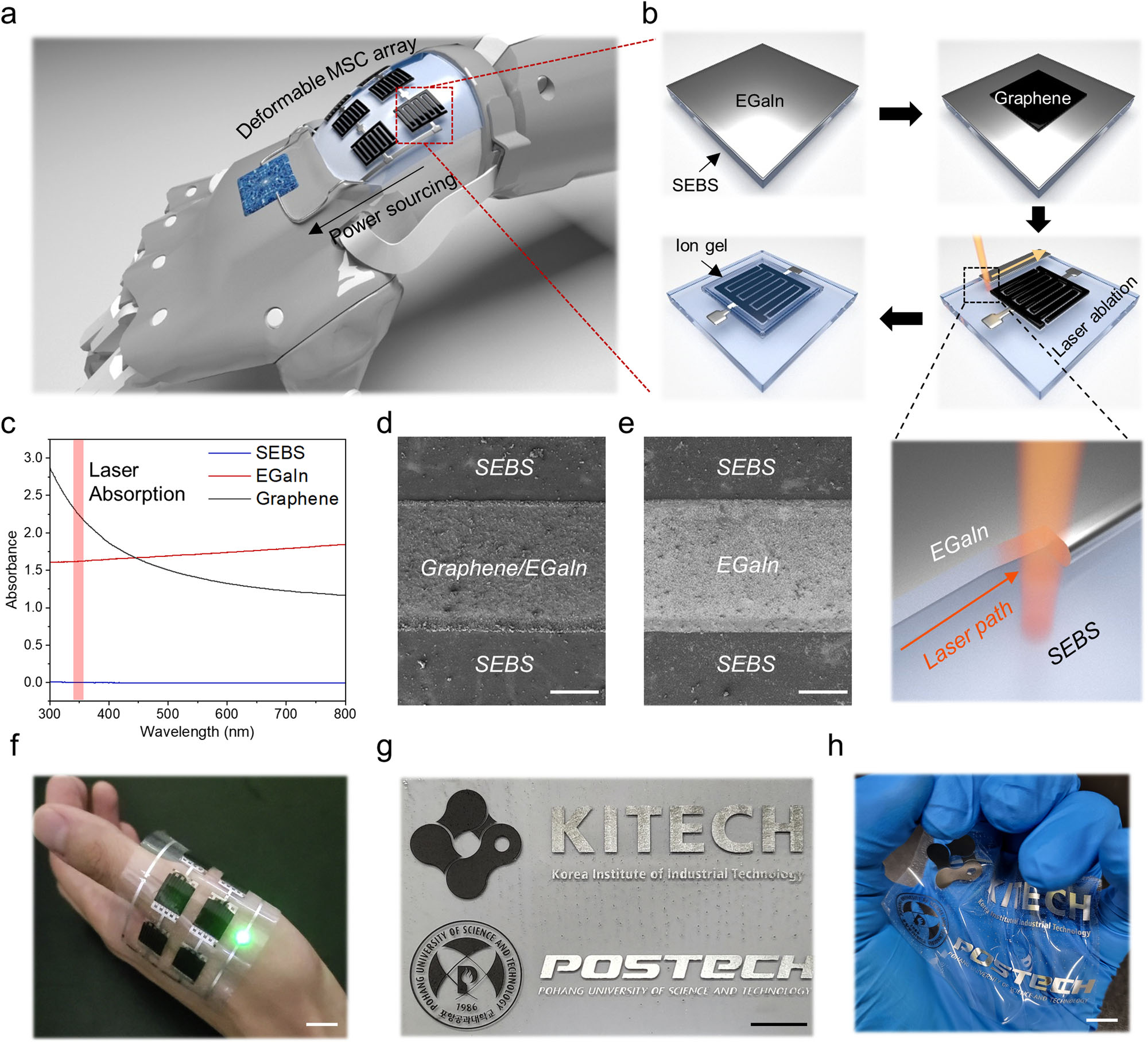

a Illustration of an built-in system comprising soft-electronics and deformable power storage part. b The fabrication technique of EGaIn-based MSC. c UV-vis spectra of SEBS, EGaIn, and graphene. FE-SEM pictures of laser ablated d Graphene/EGaIn and e EGaIn (Scale bar = 200 µm). Pictures of f institute logos, g deformed logos, and h an LED linked to the MSC circuit (Scale bar = 1 cm). (Picture: © npj Versatile Electronics)

The important thing innovation lies in the usage of eutectic gallium-indium (EGaIn), a liquid steel alloy, as the present collector. “To implement a deformable MSC, a deformable present collector is required,” Kim explains to Nanowerk. “Nonetheless, the generally used present collectors are product of brittle supplies like gold (Au). To handle this challenge, now we have chosen ‘liquid steel’ that inherently possesses the properties of a liquid and metallic conductivity.”

The fabrication course of begins with coating a skinny movie of EGaIn onto a stretchable styrene-ethylene-butylene-styrene (SEBS) substrate, adopted by the deposition of a graphene layer to function the energetic electrode materials. The researchers selectively ablate graphene and EGaIn to acquire interdigitated sample through the use of laser, exploiting the robust laser absorption of those supplies in comparison with the clear SEBS. By fastidiously tuning the laser depth, they obtain exact patterning with out damaging the underlying elastic substrate.

The selection of supplies proves essential to the success of this method. “We efficiently achieved patterning of the liquid steel by using its wonderful absorption of the laser’s wavelength,” notes Kim. “Moreover, by adjusting the depth of the laser, we prevented the injury to the substrate brought on by the warmth induced by laser, whereas each the graphene and liquid steel have been ablated by the laser.”

The SEBS substrate, which doesn’t soak up the laser wavelength, can face up to the warmth generated throughout ablation, permitting for the creation of high-resolution patterns with electrode gaps as small as 90 µm.

The ensuing MSCs exhibit spectacular efficiency, attaining areal capacitances as much as 1336 µF cm-2 whereas sustaining good price functionality. Importantly, the gadgets present no important degradation below varied mechanical deformations, together with folding, wrinkling, twisting, and stretching, even after 1000 deformation cycles.

“MSC utilizing a liquid steel present collector confirmed no change in power storage efficiency below varied mechanical deformations and even after repeated deformations,” emphasizes Kim, highlighting the potential for these gadgets to energy wearable and versatile electronics.

To show the sensible potential of their MSCs, the researchers built-in an array of gadgets with light-emitting diodes to create a stretchable lighting system. The system maintained steady operation below extreme bending, twisting, and stretching, showcasing the MSCs’ potential to reliably energy deformable electronics.

Trying forward, Kim and Yang see room for additional enchancment and thrilling potentialities for future functions. “Within the area of MSCs, concurrently attaining excessive power density and excessive deformability stays a major problem,” They notice. “It’s because, throughout mechanical deformation, not solely the interface between the present collector and the energetic materials must be effectively maintained, but in addition the power density of the energetic supplies itself have to be elevated. Subsequently, this challenge must be resolved.”

Whereas extra work is required to reinforce the mechanical sturdiness of the gel electrolyte utilized in these MSCs, the usage of laser-patterned liquid steel electrodes represents a major step ahead within the improvement of actually deformable power storage options. As wearable applied sciences proceed to advance, improvements like these will play a significant function in making certain that our gadgets can adapt to the calls for of our dynamic existence.

From good clothes that displays our well being to biomedical implants that flex with our our bodies, the way forward for wearable electronics will depend on power storage methods that aren’t solely compact and highly effective but in addition as versatile as we’re. With their distinctive mixture of liquid steel conductors, elastic substrates, and excessive electrochemical efficiency, the graphene primarily based MSCs provide an thrilling glimpse into that future, stretching the boundaries of what is potential in wearable power storage. As analysis on this area progresses, we will sit up for a brand new technology of wearable gadgets that seamlessly combine with our lives, empowered by deformable power storage options that by no means maintain us again.

By

Michael

Berger

– Michael is creator of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Expertise,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Expertise and Instruments Making Expertise Invisible

Copyright ©

Nanowerk LLC

Nanowerk Publication

Get our Nanotechnology Highlight updates to your inbox!

Thanks!

You’ve efficiently joined our subscriber checklist.

Develop into a Highlight visitor creator! Be part of our massive and rising group of visitor contributors. Have you ever simply revealed a scientific paper or produce other thrilling developments to share with the nanotechnology group? Right here is how you can publish on nanowerk.com.

[ad_2]

Supply hyperlink